Welcome to our websites!

1 月 . 30, 2025 01:14 Back to list

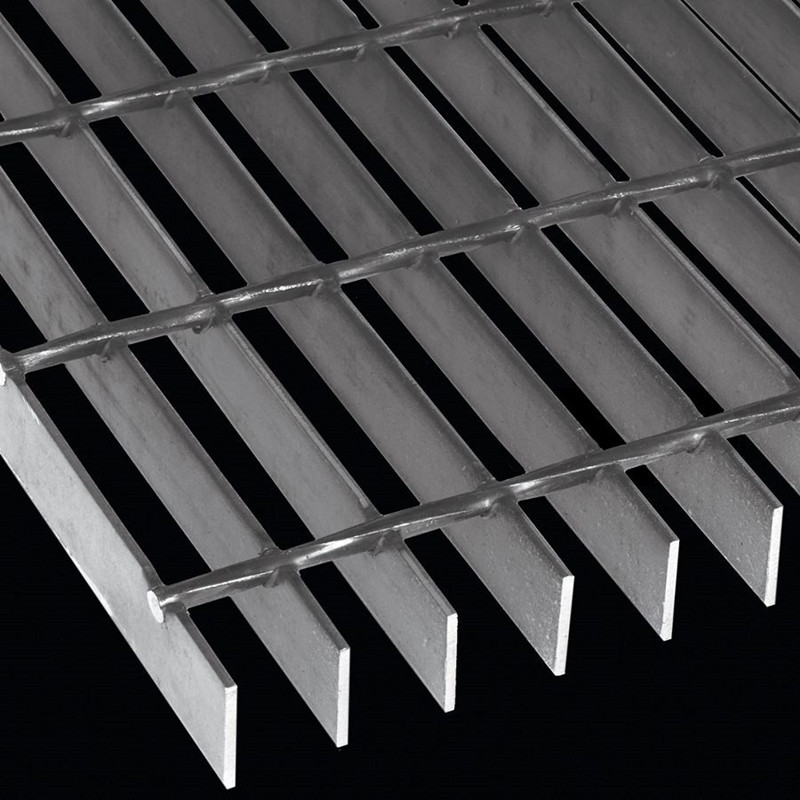

3/4-9f expanded metal mesh

Expanded metal mesh, particularly the 3/4-9f variant, stands as an exemplary product in the realm of architectural design and construction. Its unique properties offer significant advantages, making it a preferred choice for both practical and aesthetic applications. Through first-hand experience and professional expertise, the advantages of utilizing 3/4-9f expanded metal mesh become evident.

Authoritativeness in the use of 3/4-9f expanded metal mesh is reinforced by its compliance with international construction standards. The mesh’s performance meets rigorous quality controls and safety standards, providing peace of mind to engineers and architects who need assurance of reliability in their materials. This adherence to standards is crucial in maintaining the integrity and longevity of structures where the mesh is applied. Trustworthiness, an essential pillar in product selection, is reinforced by testimonials from professionals who have relied on 3/4-9f expanded metal mesh. Their experiences underline the product’s robust performance over time, resisting wear and maintaining aesthetic quality under various environmental conditions. Such endorsements add weight to the product’s credibility and reliability, often tipping the scales in its favor during the decision-making process. Innovation within the expanded metal mesh domain continues to evolve, with 3/4-9f serving as a baseline for further enhancements. Research and development efforts focus on augmenting its corrosion resistance, expanding its color range, and refining its surface finish to meet contemporary architectural demands. These ongoing advancements ensure that this type of expanded metal mesh remains at the forefront of material technology. In conclusion, the 3/4-9f expanded metal mesh stands out as a premium product, backed by experience, expert analysis, authoritative use, and a strong track record of reliability. Its broad range of applications, coupled with its inherent qualities, make it an invaluable asset in construction, architecture, and design. Those considering its use can be confident in the mesh’s ability to meet, if not exceed, their project requirements.

Authoritativeness in the use of 3/4-9f expanded metal mesh is reinforced by its compliance with international construction standards. The mesh’s performance meets rigorous quality controls and safety standards, providing peace of mind to engineers and architects who need assurance of reliability in their materials. This adherence to standards is crucial in maintaining the integrity and longevity of structures where the mesh is applied. Trustworthiness, an essential pillar in product selection, is reinforced by testimonials from professionals who have relied on 3/4-9f expanded metal mesh. Their experiences underline the product’s robust performance over time, resisting wear and maintaining aesthetic quality under various environmental conditions. Such endorsements add weight to the product’s credibility and reliability, often tipping the scales in its favor during the decision-making process. Innovation within the expanded metal mesh domain continues to evolve, with 3/4-9f serving as a baseline for further enhancements. Research and development efforts focus on augmenting its corrosion resistance, expanding its color range, and refining its surface finish to meet contemporary architectural demands. These ongoing advancements ensure that this type of expanded metal mesh remains at the forefront of material technology. In conclusion, the 3/4-9f expanded metal mesh stands out as a premium product, backed by experience, expert analysis, authoritative use, and a strong track record of reliability. Its broad range of applications, coupled with its inherent qualities, make it an invaluable asset in construction, architecture, and design. Those considering its use can be confident in the mesh’s ability to meet, if not exceed, their project requirements.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025