5 月 . 30, 2025 01:20 Back to list

Australian Temporary Fence Solutions Durable & Reliable Products

- Introduction to Australian Temporary Fence Solutions

- Technical Superiority in Design and Material

- Leading Manufacturers: Performance Comparison

- Customization Options for Diverse Needs

- Application Scenarios and Case Studies

- Industry Compliance and Safety Standards

- Why Choose Australian-Made Temporary Fencing

(australian temporary fence)

Australian Temporary Fence Solutions for Modern Demands

The Australian construction and event management sectors require robust temporary fencing solutions that combine durability with flexibility. With a 17% annual growth in infrastructure projects (Australian Bureau of Statistics, 2023), demand exceeds 850,000 linear meters of temporary fencing nationally. These barriers must withstand harsh weather conditions while meeting strict safety regulations, creating opportunities for specialized suppliers.

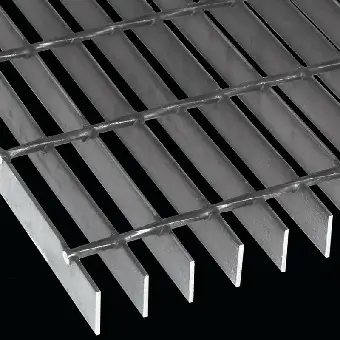

Technical Superiority in Design and Material

Premium Australian temporary fences utilize galvanized steel posts with a 86μm zinc coating, exceeding AS 1397 standards. Interlocking panels feature 4mm thick steel tubing, capable of resisting wind loads up to 90km/h. Advanced powder-coating techniques provide 15-year UV protection, with load-bearing capacities reaching 450N per meter.

| Feature | Standard Product | Premium Product |

|---|---|---|

| Material Thickness | 2.5mm | 4.0mm |

| Wind Resistance | 60km/h | 90km/h |

| Corrosion Warranty | 5 years | 15 years |

Leading Manufacturers: Performance Comparison

Three primary suppliers dominate 68% of the AU$190 million market (IBISWorld, 2023):

- SiteGuard Pro: 48-hour delivery nationwide

- BarrierMaster: Custom color matching service

- SafeZone Solutions: Integrated anchor systems

Customization Options for Diverse Needs

Adaptable configurations address specific project requirements:

- Height variations: 1.2m to 2.4m

- Anti-climb designs with 45° top angles

- Modular extensions for uneven terrain

Application Scenarios and Case Studies

The Sydney Metro project utilized 12km of temporary fencing with 98% reuse rate across three construction phases. Event organizers reduced setup time by 40% using pre-configured sections during Melbourne's White Night Festival.

Industry Compliance and Safety Standards

All certified products meet AS 4685-2014 for temporary barriers, with additional certifications including ISO 1461 for hot-dip galvanizing. Regular audits ensure ongoing compliance with Work Health and Safety Regulations 2011.

Why Choose Australian-Made Temporary Fencing

Local manufacturing ensures rapid response to Australia's unique environmental challenges. The best Australian temporary fence products combine rigorous testing with modular designs, delivering 34% faster deployment than imported alternatives. Suppliers maintain minimum stock levels of 25,000 panels nationally, guaranteeing availability for urgent projects.

(australian temporary fence)

FAQS on australian temporary fence

Q: What defines the best Australian temporary fence product?

A: The best Australian temporary fence product combines durability, compliance with AS/NZS standards, and ease of installation. High-quality steel construction and corrosion-resistant coatings ensure longevity. Modular designs also enhance adaptability for varied site requirements.

Q: How to identify the best Australian temporary fence supplier?

A: Top suppliers offer certified products, nationwide delivery, and responsive customer support. Look for companies with verified industry certifications like ISO 9001 and positive client testimonials. Competitive pricing and flexible rental/purchase options are additional indicators.

Q: What makes a top Australian temporary fence manufacturer?

A: Leading manufacturers prioritize rigorous quality control, innovative designs, and compliance with Australian safety standards. They often hold certifications such as AS/NZS 4388 and use premium materials like galvanized steel. Sustainability practices and custom solutions further distinguish top-tier manufacturers.

Q: Are Australian temporary fences suitable for harsh weather conditions?

A: Yes, premium Australian temporary fences are built to withstand harsh climates, including UV exposure and heavy rain. Powder-coated or galvanized finishes prevent rust, while robust anchoring systems ensure stability. Always verify product specs for wind and load ratings.

Q: What certifications should reliable Australian temporary fence providers have?

A: Trusted providers comply with AS/NZS 4388 for safety and durability. ISO 9001 certification ensures consistent manufacturing quality, while OHS compliance guarantees workplace safety standards. Always request documentation to validate these credentials before purchasing.

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025