Welcome to our websites!

1 月 . 15, 2025 09:20 Back to list

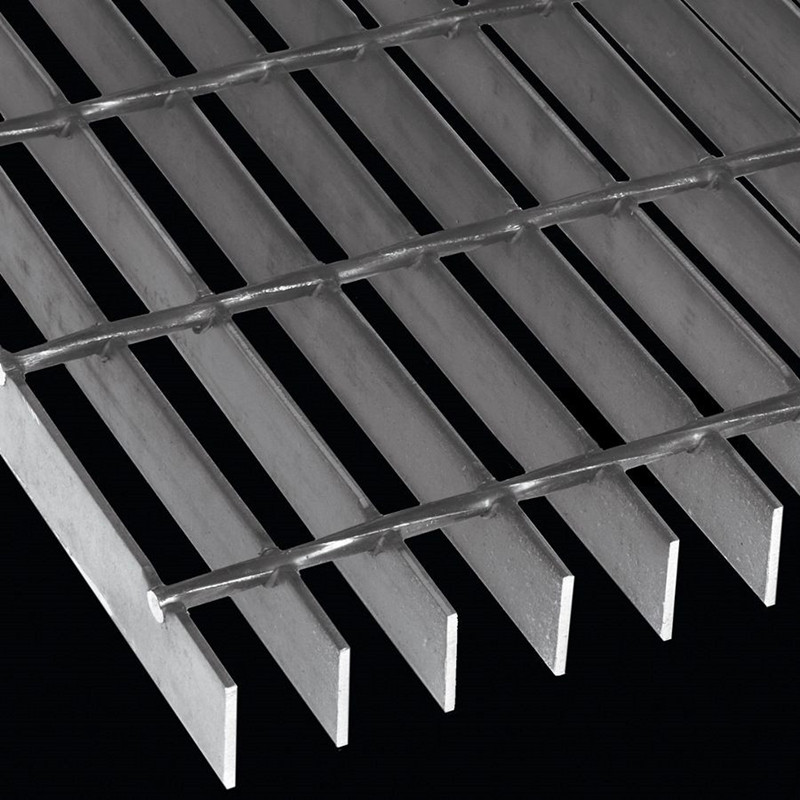

bar grating price

Navigating the world of bar grating prices involves understanding several critical factors that affect your buying decision. With years of experience in industrial products and market trends, it becomes apparent that purchasing bar grating isn't solely about cost—it’s about identifying a product that marries quality with value, expertise with reliability.

The Experience of Customization Experience teaches that custom solutions might sometimes offer the best return on investment, despite higher initial pricing. Tailored grating products address unique operational challenges that off-the-shelf products might not meet. For instance, anti-slip coatings or specific load-bearing capacities might be necessary for safety-critical environments like oil rigs or chemical plants. Working with manufacturers to understand customization options can lead to a more economical lifecycle cost by precisely aligning product capability with operational needs. Dynamic Pricing Factors The fluctuation of metal prices in global markets invariably affects bar grating costs. Monitoring indices like the London Metal Exchange provides insight into market trends, enabling both immediate cost evaluation and future price predictions. Seasonal demand, import/export tariffs, and geopolitical factors might also sway pricing, underlining the need for dynamic pricing strategies based on current events and forecasts rather than static pricing models. In conclusion, exploring bar grating prices involves more than the initial quotation. It requires a deep dive into specifications, materials science, market trends, and supplier reliability. By leveraging industry expertise and authoritative standards, while ensuring supplier trustworthiness and considering customization advantages, businesses can achieve a balance between cost and quality. Investing in informed decisions today ensures safety, productivity, and economic performance in the years to come.

The Experience of Customization Experience teaches that custom solutions might sometimes offer the best return on investment, despite higher initial pricing. Tailored grating products address unique operational challenges that off-the-shelf products might not meet. For instance, anti-slip coatings or specific load-bearing capacities might be necessary for safety-critical environments like oil rigs or chemical plants. Working with manufacturers to understand customization options can lead to a more economical lifecycle cost by precisely aligning product capability with operational needs. Dynamic Pricing Factors The fluctuation of metal prices in global markets invariably affects bar grating costs. Monitoring indices like the London Metal Exchange provides insight into market trends, enabling both immediate cost evaluation and future price predictions. Seasonal demand, import/export tariffs, and geopolitical factors might also sway pricing, underlining the need for dynamic pricing strategies based on current events and forecasts rather than static pricing models. In conclusion, exploring bar grating prices involves more than the initial quotation. It requires a deep dive into specifications, materials science, market trends, and supplier reliability. By leveraging industry expertise and authoritative standards, while ensuring supplier trustworthiness and considering customization advantages, businesses can achieve a balance between cost and quality. Investing in informed decisions today ensures safety, productivity, and economic performance in the years to come.

Share

Next:

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025