8 月 . 18, 2024 00:12 Back to list

CE Certification for Expanded Mesh Products and Their Applications in Various Industries

CE Certification for Expanded Mesh Ensuring Quality and Safety

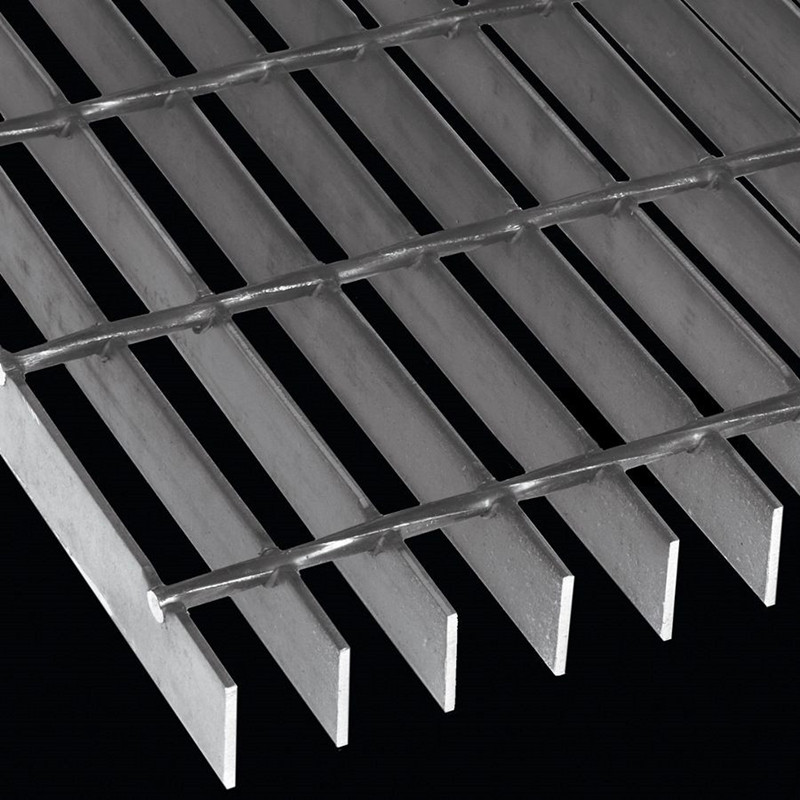

Expanded mesh, a versatile material made by stretching and cutting metal sheets, is widely utilized in various industries for applications ranging from architectural facades to industrial safety barriers. Ensuring the quality and safety of expanded mesh products is crucial, especially in applications where public safety is involved. This is where CE certification plays a vital role.

Understanding CE Certification

CE marking is a declaration by manufacturers that their products meet the essential requirements of relevant European health, safety, and environmental protection legislation. The initials CE stand for Conformité Européenne, which translates to European Conformity. Products that receive CE marking indicate compliance with the European Union (EU) directives, allowing them to be sold within the European Economic Area (EEA).

For expanded mesh products, CE certification signifies that they have undergone rigorous testing and evaluation to ensure they meet the required standards. These standards cover various aspects, including mechanical properties, durability, and safety performance. Obtaining CE certification is not just a regulatory requirement but also serves as a benchmark of quality that can enhance a manufacturer’s reputation.

Importance of CE Certification for Expanded Mesh

1. Safety Assurance One of the primary reasons for obtaining CE certification is to ensure the safety of expanded mesh products. These materials are often used in critical applications such as construction, automotive, and aerospace industries, where even minor faults can have severe consequences. CE certification assures users that the product has been tested for potential hazards and meets safety standards.

ce certification expanded mesh

2. Market Access CE certification is a prerequisite for selling products in the European market. For manufacturers, having CE-marked expanded mesh allows them greater access to the European market and increases their competitiveness. This compliance not only facilitates smoother trade but also opens up additional markets where safety assurance is a significant concern.

3. Quality Control Undergoing the CE certification process requires rigorous quality control and testing of expanded mesh products. Manufacturers must demonstrate that their products consistently meet specified standards. This not only enhances product reliability but also contributes to reduced liability and warranty claims, as certified products are less likely to encounter issues.

4. Environmental and Health Compliance CE certification includes adherence to environmental and health regulations. This is particularly important in today’s market, where sustainability is a growing concern. By ensuring that expanded mesh products are manufactured with environmentally friendly processes and materials, manufacturers can attract eco-conscious customers and comply with EU regulations regarding environmental impacts.

5. Consumer Confidence When consumers see the CE mark on expanded mesh products, it instills confidence in their minds regarding the product’s quality and safety. This is especially true in industries where safety is paramount. A CE marking can be a decisive factor for consumers when choosing between different suppliers.

Conclusion

In conclusion, CE certification for expanded mesh is an essential aspect of product quality and safety that cannot be overlooked. It ensures products meet required standards, provides manufacturers with market access, and builds consumer confidence. As industries increasingly prioritize safety and compliance, the importance of CE certification will likely continue to grow. For manufacturers of expanded mesh, investing in CE certification not only demonstrates commitment to quality but also opens up a world of opportunity in highly regulated markets. By adhering to these standards, manufacturers can foster a culture of safety and reliability—key aspects in building a successful and sustainable business.

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025