8 月 . 18, 2024 21:06 Back to list

China Manufacturer of PVC Coated Chain Link Mesh Fences for Durable and Secure Enclosures

The Rise of PVC Coated Chain Link Mesh Fences in China

In recent years, the demand for high-quality fencing solutions has surged globally, particularly in residential, commercial, and industrial sectors. Among various fencing options, PVC coated chain link mesh fences have gained considerable popularity. This article explores the manufacturing landscape of these fences in China, highlighting their characteristics, advantages, and the factory processes involved in their production.

Understanding PVC Coated Chain Link Mesh Fences

PVC coated chain link fences consist of woven steel wire that is coated with polyvinyl chloride (PVC) to enhance durability and aesthetic appeal. The wire's base material is typically galvanized steel, providing a strong yet lightweight framework. The PVC coating not only protects against rust and weather corrosion but also allows for a variety of color choices, aligning with diverse landscaping and architectural preferences.

Advantages of PVC Coated Chain Link Fences

1. Durability One of the primary benefits of PVC coated chain link fences is their longevity. The PVC coating acts as a barrier, protecting the steel from moisture and environmental elements that can lead to rusting and degradation. This means that such fences can last for many years, even in harsh weather conditions.

2. Low Maintenance Unlike wooden fences that require regular staining or paint to maintain their appearance, PVC coated fences are relatively maintenance-free. A simple rinse with water is often sufficient to keep them looking new.

3. Aesthetic Versatility The availability of various colors in PVC coatings allows homeowners and businesses to choose options that complement their property design. This aesthetic flexibility has made them a desirable choice for both residential and commercial applications.

4. Cost-Effectiveness PVC coated chain link fences are often more affordable than solid panel fences, making them a budget-friendly solution for securing properties. Their durability also means that the long-term ownership costs (maintenance and replacement) are lower.

china pvc coated chain link mesh fence factory

Manufacturing Process

China has established itself as a leader in the production of PVC coated chain link mesh fences, with numerous factories equipped with modern technology to ensure high-quality output. The manufacturing process involves several critical stages

1. Wire Selection and Galvanization The process begins with selecting high-quality steel wire, which is then galvanized to prevent rusting. The galvanization process involves coating the steel with a layer of zinc, providing a strong foundation for the subsequent PVC coating.

2. Weaving the Mesh Once the wire is ready, it is woven into the desired mesh pattern using specialized machines. The weaving process ensures that the fence maintains strength while allowing for flexibility and easy installation.

3. PVC Coating After weaving, the mesh is treated with a PVC coating. This can be achieved through different methods, including dipping, spraying, or extrusion. The coated mesh is then cured in an oven, allowing the PVC to adhere firmly to the wire.

4. Quality Control and Packaging Finally, the completed vinyl-coated chain link fences undergo rigorous quality checks to meet international standards. Any defective products are discarded or repaired. Once approved, the fences are carefully packaged and shipped worldwide.

Conclusion

The market for PVC coated chain link mesh fences in China is thriving, driven by both domestic and international demand. With their blend of durability, low maintenance, and aesthetic appeal, these fences offer a practical and attractive fencing solution for various applications. As factories continue to innovate and improve their manufacturing processes, the future for PVC coated chain link mesh fences looks promising, further solidifying China's position as a global leader in the fencing industry.

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

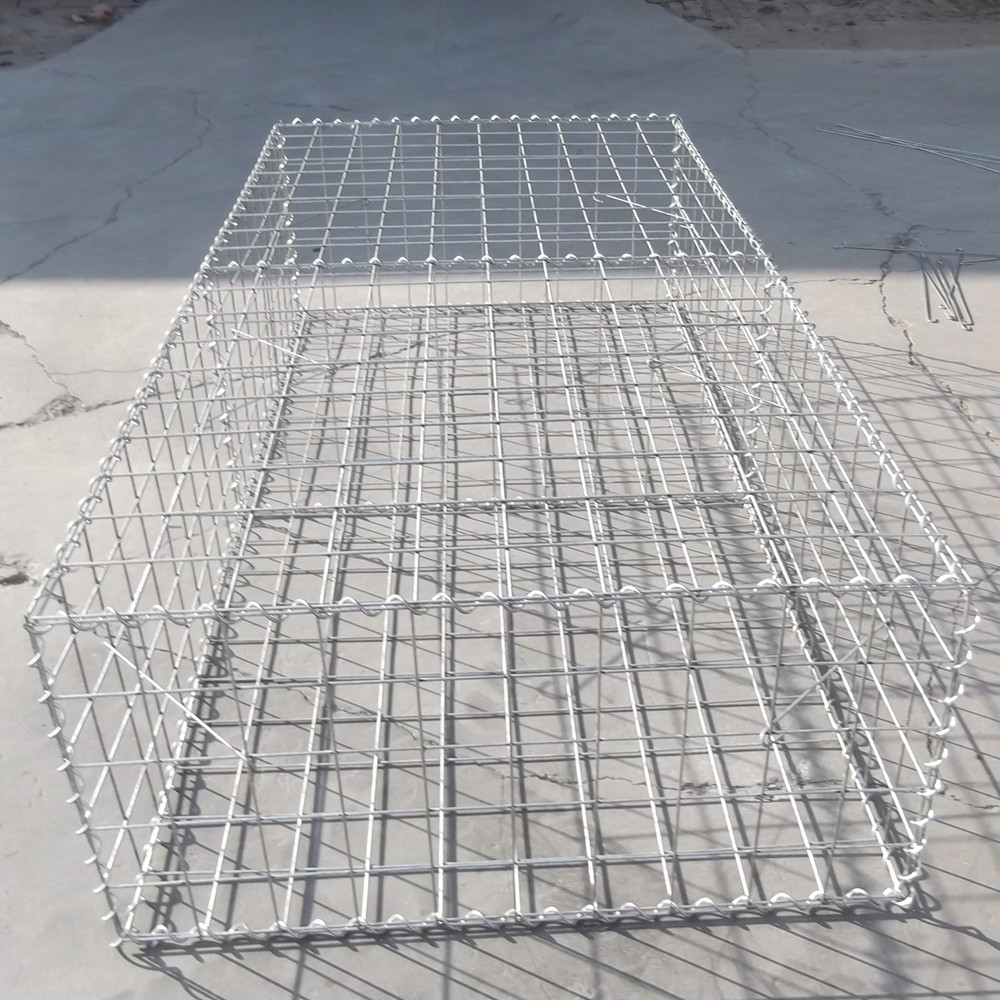

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025