Welcome to our websites!

2 月 . 16, 2025 05:31 Back to list

china 3/8 inch welded wire mesh

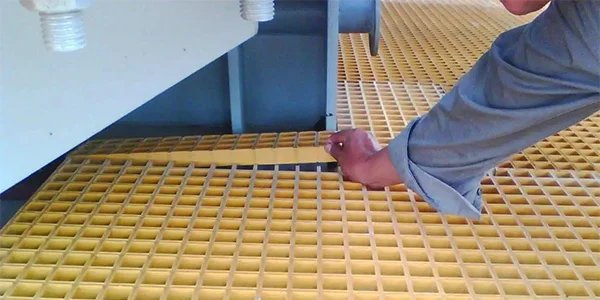

Welded wire mesh, particularly the popular 3/8 inch type, forms an integral component in various construction and industrial applications. Its versatility, strength, and ease of installation make it a preferred choice for both domestic and commercial purposes. When considering purchasing and utilizing this specific size of welded wire mesh, it is essential to delve into the product's properties, benefits, and implementations to harness its full potential effectively.

For professionals in the construction and industrial sectors, selecting high-quality 3/8 inch welded wire mesh is crucial. Reliable suppliers adhere to stringent manufacturing standards to ensure consistent quality across their product range. Certifications and compliance with industry regulations provide assurance that the mesh will perform as expected, meeting both structural and safety standards. Furthermore, understanding the different grades and thicknesses available can guide decision-making when selecting the right mesh for a particular application. Engineers and architects often collaborate, using this information to integrate welded wire mesh seamlessly into the design and functionality of their projects. Technical manuals and product specifications from reputable manufacturers can serve as valuable resources in this regard, providing detailed insights into performance parameters and testing results. The environmental impact of construction materials cannot be overlooked, and welded wire mesh is no exception. Its recyclable nature means that even at the end of its lifecycle, the metal can be repurposed, contributing to sustainable building practices. This aspect is increasingly important as consumers and companies alike prioritize environmentally-friendly solutions, aligning with global efforts to mitigate climate change. In conclusion, the 3/8 inch welded wire mesh stands as a testament to the fusion of form and function. Its robust construction, versatility, and protective treatments empower architects, engineers, and DIY enthusiasts to tackle a wide array of projects with confidence. By opting for this reliable material, users not only benefit from its practical advantages but also contribute to sustainable practices that support a greener future.

For professionals in the construction and industrial sectors, selecting high-quality 3/8 inch welded wire mesh is crucial. Reliable suppliers adhere to stringent manufacturing standards to ensure consistent quality across their product range. Certifications and compliance with industry regulations provide assurance that the mesh will perform as expected, meeting both structural and safety standards. Furthermore, understanding the different grades and thicknesses available can guide decision-making when selecting the right mesh for a particular application. Engineers and architects often collaborate, using this information to integrate welded wire mesh seamlessly into the design and functionality of their projects. Technical manuals and product specifications from reputable manufacturers can serve as valuable resources in this regard, providing detailed insights into performance parameters and testing results. The environmental impact of construction materials cannot be overlooked, and welded wire mesh is no exception. Its recyclable nature means that even at the end of its lifecycle, the metal can be repurposed, contributing to sustainable building practices. This aspect is increasingly important as consumers and companies alike prioritize environmentally-friendly solutions, aligning with global efforts to mitigate climate change. In conclusion, the 3/8 inch welded wire mesh stands as a testament to the fusion of form and function. Its robust construction, versatility, and protective treatments empower architects, engineers, and DIY enthusiasts to tackle a wide array of projects with confidence. By opting for this reliable material, users not only benefit from its practical advantages but also contribute to sustainable practices that support a greener future.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025