Welcome to our websites!

2 月 . 15, 2025 18:02 Back to list

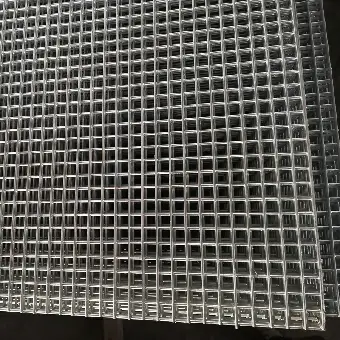

Steel Expanded Metal Mesh Fence

When it comes to modern landscape architecture and civil engineering, the demand for durable, sustainable, and versatile materials is on the rise. Gabion mesh, a type of product made from galvanised or PVC-coated wire, has become a staple solution across various projects worldwide, particularly in China, a leading manufacturer and innovator in this field.

Authority and trust in gabion mesh as a product stem from its historical usage and the trust users have placed in it globally. This trust is shared by civil engineers and landscape architects who see it as a reliable material for critical infrastructure projects. Furthermore, gabion mesh has undergone extensive testing and refinement to align with environmental regulations and sustainability standards. Trustworthiness is a critical factor when selecting construction materials, particularly for large-scale projects where safety and longevity are paramount. Chinese manufacturers of gabion mesh have consistently provided certified products that comply with both domestic and international quality standards. Many companies offer warranties on their galvanised and PVC-coated products, reflecting their confidence in the durability and effectiveness of their meshes. An interesting aspect of gabion mesh applications is its growing role in eco-friendly development. The use of natural stone fill encapsulated in gabion mesh not only strengthens physical structures but also supports local ecosystems by providing habitats for small wildlife and facilitating natural vegetation. This aligns well with global trends towards sustainable construction and development, making it a favored choice among environmentally-conscious engineers and architects. Furthermore, China’s vast manufacturing capacity and expertise means it can supply gabion mesh in large volumes required for extensive projects without compromising on quality. This scalability is particularly crucial for international projects seeking reliable ongoing supply, reinforcing China's position as a pivotal player in the global construction materials market. In conclusion, the utilization of gabion mesh within construction projects signifies an intersection of modern engineering needs with traditional materials sensibility. Chinese innovations and advancements in gabion mesh production not only address fundamental construction needs but also contribute towards more sustainable and aesthetically pleasing solutions. As a product, it stands as an exemplar of how engineering ingenuity and manufacturing prowess can coalesce to tackle diverse structural challenges while supporting sustainable practices.

Authority and trust in gabion mesh as a product stem from its historical usage and the trust users have placed in it globally. This trust is shared by civil engineers and landscape architects who see it as a reliable material for critical infrastructure projects. Furthermore, gabion mesh has undergone extensive testing and refinement to align with environmental regulations and sustainability standards. Trustworthiness is a critical factor when selecting construction materials, particularly for large-scale projects where safety and longevity are paramount. Chinese manufacturers of gabion mesh have consistently provided certified products that comply with both domestic and international quality standards. Many companies offer warranties on their galvanised and PVC-coated products, reflecting their confidence in the durability and effectiveness of their meshes. An interesting aspect of gabion mesh applications is its growing role in eco-friendly development. The use of natural stone fill encapsulated in gabion mesh not only strengthens physical structures but also supports local ecosystems by providing habitats for small wildlife and facilitating natural vegetation. This aligns well with global trends towards sustainable construction and development, making it a favored choice among environmentally-conscious engineers and architects. Furthermore, China’s vast manufacturing capacity and expertise means it can supply gabion mesh in large volumes required for extensive projects without compromising on quality. This scalability is particularly crucial for international projects seeking reliable ongoing supply, reinforcing China's position as a pivotal player in the global construction materials market. In conclusion, the utilization of gabion mesh within construction projects signifies an intersection of modern engineering needs with traditional materials sensibility. Chinese innovations and advancements in gabion mesh production not only address fundamental construction needs but also contribute towards more sustainable and aesthetically pleasing solutions. As a product, it stands as an exemplar of how engineering ingenuity and manufacturing prowess can coalesce to tackle diverse structural challenges while supporting sustainable practices.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025