Welcome to our websites!

2 月 . 16, 2025 10:01 Back to list

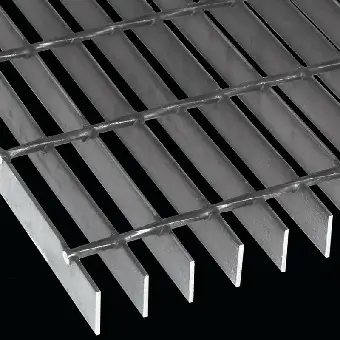

358 Anti Climb Welded Wire Mesh Fence

Galvanized window screens have long been a staple in homes and commercial properties for their durability and effectiveness in keeping unwanted elements at bay. As someone deeply entrenched in the industry, I've observed firsthand the key characteristics and benefits that set these screens apart.

Trustworthiness forms the backbone of any consumer's decision-making process. Galvanized window screens undergo rigorous quality assurance processes, from material selection to the final product inspection. This rigorous approach demystifies any potential doubts regarding durability and effectiveness. Moreover, warranties provided by reputable manufacturers further establish a layer of trust, offering consumers peace of mind that any defects will be addressed promptly. Those seeking to install or replace window screens quickly realize that galvanized options are not only cost-effective, but they also offer the best return on investment in the long run. Their resistance to wear and tear means fewer replacements and repairs, ultimately translating to reduced maintenance costs. This economic advantage, coupled with their environmental sustainability due to less frequent replacement needs, heightens their appeal among eco-conscious consumers. In the practical application, users often appreciate the ease of installation associated with galvanized window screens. Many products come with straightforward fitting instructions, allowing even DIY enthusiasts to install them without professional assistance. This ease of application is particularly valuable for those renovating or building in remote areas where access to professional installers might be limited. Ultimately, the decision to choose galvanized window screens boils down to a blend of practicality and peace of mind. Their unparalleled strength, longevity, and resistance to environmental factors make them a standout choice for anyone looking to safeguard their home or business. As industry insights suggest, investing in galvanized window screens is not just about buying a product; it’s about committing to a long-lasting solution that aligns with both personal safety and aesthetic satisfaction. With continuing advancements in manufacturing techniques, the future for galvanized window screens looks promising, ensuring they remain a relevant and beneficial choice for years to come.

Trustworthiness forms the backbone of any consumer's decision-making process. Galvanized window screens undergo rigorous quality assurance processes, from material selection to the final product inspection. This rigorous approach demystifies any potential doubts regarding durability and effectiveness. Moreover, warranties provided by reputable manufacturers further establish a layer of trust, offering consumers peace of mind that any defects will be addressed promptly. Those seeking to install or replace window screens quickly realize that galvanized options are not only cost-effective, but they also offer the best return on investment in the long run. Their resistance to wear and tear means fewer replacements and repairs, ultimately translating to reduced maintenance costs. This economic advantage, coupled with their environmental sustainability due to less frequent replacement needs, heightens their appeal among eco-conscious consumers. In the practical application, users often appreciate the ease of installation associated with galvanized window screens. Many products come with straightforward fitting instructions, allowing even DIY enthusiasts to install them without professional assistance. This ease of application is particularly valuable for those renovating or building in remote areas where access to professional installers might be limited. Ultimately, the decision to choose galvanized window screens boils down to a blend of practicality and peace of mind. Their unparalleled strength, longevity, and resistance to environmental factors make them a standout choice for anyone looking to safeguard their home or business. As industry insights suggest, investing in galvanized window screens is not just about buying a product; it’s about committing to a long-lasting solution that aligns with both personal safety and aesthetic satisfaction. With continuing advancements in manufacturing techniques, the future for galvanized window screens looks promising, ensuring they remain a relevant and beneficial choice for years to come.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025