12 月 . 04, 2024 09:23 Back to list

Top Steel Grating Manufacturers in China and Their Key Offerings

China's Steel Grating Factories A Comprehensive Overview

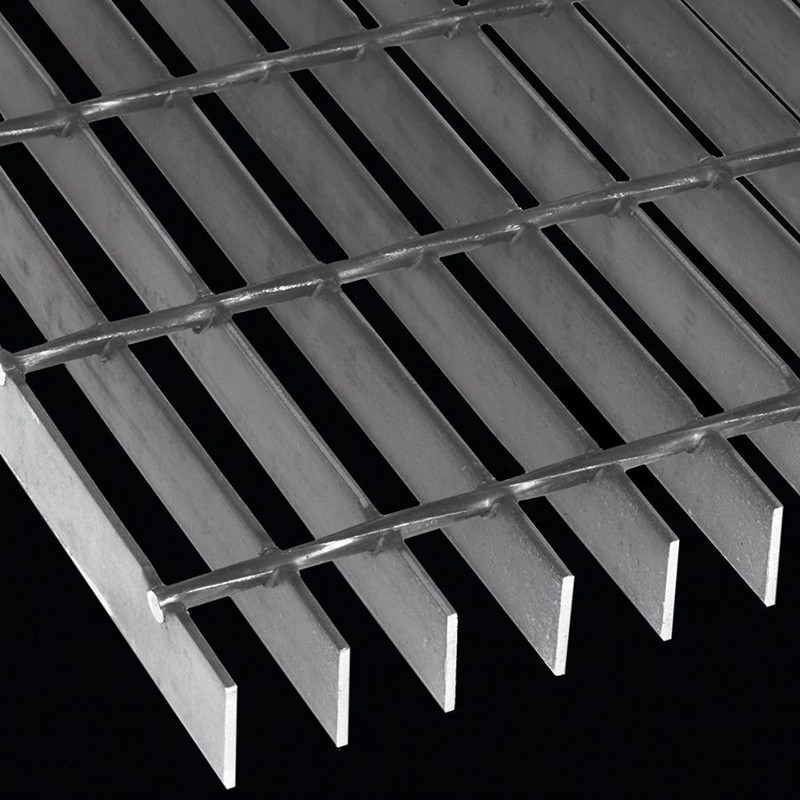

Steel grating is an essential component in various industrial applications, characterized by its durability, strength, and versatility. In recent years, China's steel grating factories have gained prominence globally, providing high-quality products for diverse industries. This article examines the key aspects of these factories, including their production processes, product types, market influence, and future prospects.

An Insight into China’s Steel Grating Manufacturing

China is the largest producer of steel in the world and has developed a robust industrial infrastructure that supports the manufacture of steel products, including steel grating. Steel grating is produced by welding together heavy-duty steel bars, creating a matrix of spaces conducive to drainage while providing a solid walking surface. The manufacturing process involves advanced techniques, including CNC cutting and automated welding, which enhance precision and efficiency.

Types of Steel Grating

Chinese manufacturers produce various types of steel grating to meet the needs of different sectors. Common types include

1. Bar Grating This is the most popular form of steel grating and is used for walkways, platforms, and drain covers. It is known for its strength and resistance to heavy loads. 2. Expanded Metal Grating Made from sheets of steel that are stretched to form a mesh pattern, this type is lightweight and offers excellent ventilation.

3. Stainless Steel Grating This variant is popular in environments where corrosion resistance is crucial, such as food processing and chemical industries.

Market Influence of Chinese Factories

The global steel grating market has increasingly relied on Chinese manufacturers due to their competitive pricing, efficient production capabilities, and high-volume outputs. Countries in North America, Europe, and Asia import significant quantities of Chinese steel grating to meet their infrastructure needs. These products find applications in construction, municipal engineering, oil and gas industries, and wastewater treatment facilities.

china steel grating factories

Chinese factories are renowned for their ability to scale production quickly, accommodating both large and small orders. This flexibility is a significant advantage, especially during times of economic fluctuations or when unexpected surges in demand occur.

Quality and Standards

Quality is paramount in steel grating manufacturing, and many Chinese factories adhere to international standards such as ISO 9001 for quality management systems. Additionally, many factories are certified by ASTM and other relevant bodies, ensuring that their products meet stringent safety and quality requirements. Continuous investment in technology and training has resulted in enhanced manufacturing capabilities, leading to improved product quality and decreased defects.

Environmental Considerations

With the rise of global awareness surrounding environmental issues, Chinese steel grating factories are increasingly implementing sustainable practices. This includes recycling scrap metal, reducing emissions during production, and utilizing eco-friendly materials. Government regulations and global market demands push factories to adopt greener practices, enhancing their appeal to overseas buyers who prioritize sustainability.

Future Prospects

The future of China’s steel grating factories appears promising. With ongoing infrastructure development projects both domestically and internationally, the demand for steel grating is expected to remain strong. The Belt and Road Initiative, aimed at enhancing trade routes, is likely to further boost the market for steel products, including grating.

Moreover, innovations in manufacturing processes, including automation and digitization, will continue to enhance productivity and reduce costs. Chinese manufacturers are also exploring new markets and applications, particularly in the renewable energy sector, which demands high-quality materials for solar and wind energy installations.

Conclusion

China’s steel grating factories are pivotal in the global steel market, driven by their manufacturing capabilities, diverse product offerings, and commitment to quality. As they continue to adapt to emerging trends and global demands, these factories will play a crucial role in meeting the infrastructure needs of the 21st century. With a focus on sustainability and innovation, they are not only shaping the future of manufacturing in China but also impacting industries worldwide.

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025