Welcome to our websites!

1 月 . 19, 2025 01:48 Back to list

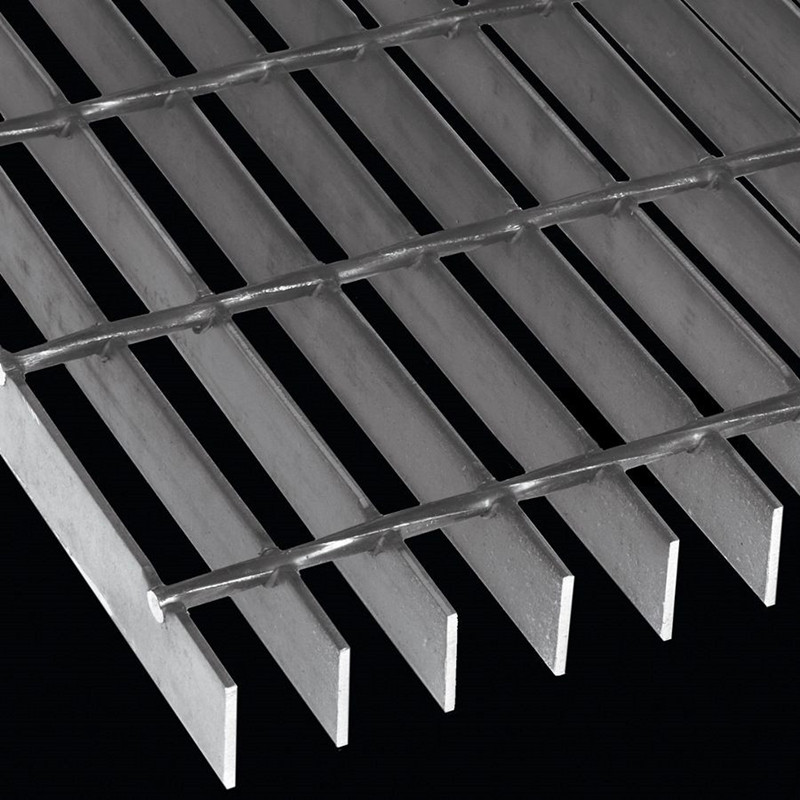

concrete wire mesh

Concrete wire mesh, often an understated component in the construction industry, plays a crucial role in reinforcing concrete structures, enhancing their strength, durability, and longevity. This woven grid of steel wires is embedded in concrete to improve its tensile properties, making it indispensable in modern building and infrastructure projects. For contractors, engineers, and builders seeking reliable and efficient reinforcement solutions, understanding the intricacies of concrete wire mesh is paramount.

Another critical aspect of effective wire mesh implementation is understanding its limitations and complementing it with other reinforcement methods when necessary. In certain applications, combining wire mesh with rebar may offer additional support, countering more complex stresses and providing an additional layer of safety. This dual-approach is particularly beneficial in areas prone to seismic activity or where structural loads are exceptionally high. In today's construction landscape, sustainability and efficiency are key concerns. Many modern wire mesh products are made from recycled materials, contributing to a project's overall sustainability goals. Furthermore, the use of wire mesh can enhance a project's efficiency. By mitigating crack formation and subsequent repairs, wire mesh reduces maintenance costs and prolongs the lifespan of concrete structures. Despite its simplicity, the role wire mesh plays in construction cannot be overemphasized. Those in the construction industry looking to deepen their expertise in building materials should prioritize understanding the nuances of concrete wire mesh. From choosing the right product to executing flawless installations, the benefits of doing so are significant. Concrete wire mesh is not merely a reinforcement solution—it's a cornerstone of modern construction that supports innovation, efficiency, and sustainability. Project managers and builders seeking to enhance their projects' quality and durability will find that investing in high-quality wire mesh and skilled installation pays substantial dividends in the long run. As an expert in this field, ensuring the highest standards of quality and safety in every project aligns with both industry best practices and customer expectations. Trust in this essential material is built through thorough knowledge, verified quality, and reliable application techniques, setting the foundation for lasting success in diverse construction endeavors.

Another critical aspect of effective wire mesh implementation is understanding its limitations and complementing it with other reinforcement methods when necessary. In certain applications, combining wire mesh with rebar may offer additional support, countering more complex stresses and providing an additional layer of safety. This dual-approach is particularly beneficial in areas prone to seismic activity or where structural loads are exceptionally high. In today's construction landscape, sustainability and efficiency are key concerns. Many modern wire mesh products are made from recycled materials, contributing to a project's overall sustainability goals. Furthermore, the use of wire mesh can enhance a project's efficiency. By mitigating crack formation and subsequent repairs, wire mesh reduces maintenance costs and prolongs the lifespan of concrete structures. Despite its simplicity, the role wire mesh plays in construction cannot be overemphasized. Those in the construction industry looking to deepen their expertise in building materials should prioritize understanding the nuances of concrete wire mesh. From choosing the right product to executing flawless installations, the benefits of doing so are significant. Concrete wire mesh is not merely a reinforcement solution—it's a cornerstone of modern construction that supports innovation, efficiency, and sustainability. Project managers and builders seeking to enhance their projects' quality and durability will find that investing in high-quality wire mesh and skilled installation pays substantial dividends in the long run. As an expert in this field, ensuring the highest standards of quality and safety in every project aligns with both industry best practices and customer expectations. Trust in this essential material is built through thorough knowledge, verified quality, and reliable application techniques, setting the foundation for lasting success in diverse construction endeavors.

Share

Next:

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025