Welcome to our websites!

1 月 . 31, 2025 05:40 Back to list

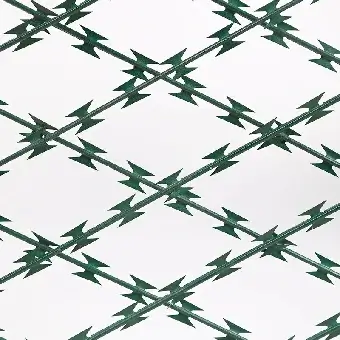

Chain link wire mesh fence

Selecting the right expanded metal mesh sheet size is crucial for optimizing applications in industries ranging from construction to automotive manufacturing. Understanding these mesh sheets' nuanced features and variations could significantly enhance project outcomes, offering both structural integrity and aesthetic appeal. This article dives deep into these considerations to provide a comprehensive guide for industrial experts and project managers.

3. Strand and Bond Dimensions The strand is the material forming the mesh's border, while bonds are the intersections. Choosing the right dimensions affects the structural integrity and appearance. Large strands with tight bonds will provide maximum strength but may reduce visibility and airflow. Smaller strands, conversely, allow for more transparency and ventilation but might sacrifice some structural robustness. 4. Material Consideration Standard materials include aluminum, stainless steel, and carbon steel, each offering unique benefits. Aluminum is lightweight and corrosion-resistant, ideal for marine environments. Stainless steel provides exceptional strength and durability, suitable for heavy-duty industrial usage. Carbon steel is an economical option for structural applications where corrosion resistance is not a primary concern. 5. Application-Specific Recommendations - Architectural Uses Decorative meshes often require fine, detailed patterns. Here, the choice of aluminum with a thinner gauge and smaller strand size may be more appropriate. - Safety and Security For handrails and guards, stainless steel with larger strands and bonds is recommended due to its strength and durability. - Industrial Ventilation Applications requiring airflow like machine covers should use larger mesh openings to promote air circulation without compromising on safety. When selecting expanded metal mesh sheet sizes, engaging with a provider who can offer deep expertise in both standard and custom sizing is invaluable. Prompt consultation with experts will ensure that all considerations are met, optimizing both the functional and aesthetic requirements of your project. Ultimately, choosing the correct expanded metal mesh sheet sizes is as much about artistic vision as it is about engineering practicality. This guide serves as a resource, ensuring that each decision enhances your project's overall success, maintains safety, and upholds structural integrity. This knowledge empowers you to make informed, authoritative decisions in an industry that values both precision and creativity.

3. Strand and Bond Dimensions The strand is the material forming the mesh's border, while bonds are the intersections. Choosing the right dimensions affects the structural integrity and appearance. Large strands with tight bonds will provide maximum strength but may reduce visibility and airflow. Smaller strands, conversely, allow for more transparency and ventilation but might sacrifice some structural robustness. 4. Material Consideration Standard materials include aluminum, stainless steel, and carbon steel, each offering unique benefits. Aluminum is lightweight and corrosion-resistant, ideal for marine environments. Stainless steel provides exceptional strength and durability, suitable for heavy-duty industrial usage. Carbon steel is an economical option for structural applications where corrosion resistance is not a primary concern. 5. Application-Specific Recommendations - Architectural Uses Decorative meshes often require fine, detailed patterns. Here, the choice of aluminum with a thinner gauge and smaller strand size may be more appropriate. - Safety and Security For handrails and guards, stainless steel with larger strands and bonds is recommended due to its strength and durability. - Industrial Ventilation Applications requiring airflow like machine covers should use larger mesh openings to promote air circulation without compromising on safety. When selecting expanded metal mesh sheet sizes, engaging with a provider who can offer deep expertise in both standard and custom sizing is invaluable. Prompt consultation with experts will ensure that all considerations are met, optimizing both the functional and aesthetic requirements of your project. Ultimately, choosing the correct expanded metal mesh sheet sizes is as much about artistic vision as it is about engineering practicality. This guide serves as a resource, ensuring that each decision enhances your project's overall success, maintains safety, and upholds structural integrity. This knowledge empowers you to make informed, authoritative decisions in an industry that values both precision and creativity.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025