Welcome to our websites!

1 月 . 31, 2025 06:26 Back to list

High Security W&D Section Galvanized Steel Palisade Fencing

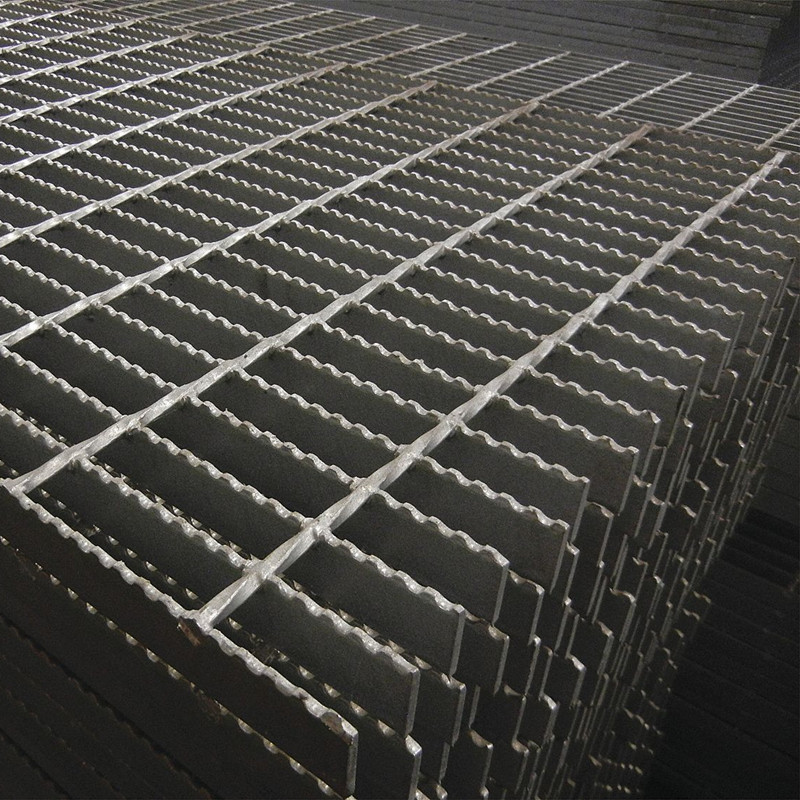

Expanded metal mesh plays a significant role across diverse industries, including construction, automotive, and architectural design. Among its critical parameters, thickness stands out, significantly impacting the mesh's performance and application versatility. Understanding the nuances of expanded metal mesh thickness is crucial for selecting the right materials for specific applications.

Authoritative industry standards guide the manufacturing and application of expanded metal mesh. ASTM standards, for instance, provide methodologies to evaluate the physical and mechanical properties of these materials, helping users discern the appropriate thickness for specific applications. Compliance with such standards ensures reliability and performance consistency, which is indispensable for projects requiring precision and safety. Trust in the material is crucial to its effective application. Companies showcasing a strong track record of quality manufacturing boost their legitimacy by offering expanded metal meshes with consistent thickness and other vital specifications. Advanced production techniques and quality control protocols are essential to maintain such standards, ensuring that each batch adheres to precise thickness measurements, thereby bolstering trust among professional engineers and architects. Conclusively, selecting the right expanded metal mesh thickness is a multifaceted decision, influenced by factors such as load requirements, environmental conditions, and intended application-specific needs. Real-world experience underscores the importance of consulting with experts who can provide insights into the optimal thickness for specific projects. By understanding these nuances, stakeholders can make informed decisions, ensuring both efficiency and safety in the utilization of expanded metal mesh. As industries continue to innovate, the demand for precise, reliable materials will grow, making expanded metal mesh thickness a topic of enduring relevance and continued research. Manufacturers and users alike must remain vigilant, leveraging expertise, authoritative guidelines, and trust in proven practices to harness the full potential of expanded metal meshes.

Authoritative industry standards guide the manufacturing and application of expanded metal mesh. ASTM standards, for instance, provide methodologies to evaluate the physical and mechanical properties of these materials, helping users discern the appropriate thickness for specific applications. Compliance with such standards ensures reliability and performance consistency, which is indispensable for projects requiring precision and safety. Trust in the material is crucial to its effective application. Companies showcasing a strong track record of quality manufacturing boost their legitimacy by offering expanded metal meshes with consistent thickness and other vital specifications. Advanced production techniques and quality control protocols are essential to maintain such standards, ensuring that each batch adheres to precise thickness measurements, thereby bolstering trust among professional engineers and architects. Conclusively, selecting the right expanded metal mesh thickness is a multifaceted decision, influenced by factors such as load requirements, environmental conditions, and intended application-specific needs. Real-world experience underscores the importance of consulting with experts who can provide insights into the optimal thickness for specific projects. By understanding these nuances, stakeholders can make informed decisions, ensuring both efficiency and safety in the utilization of expanded metal mesh. As industries continue to innovate, the demand for precise, reliable materials will grow, making expanded metal mesh thickness a topic of enduring relevance and continued research. Manufacturers and users alike must remain vigilant, leveraging expertise, authoritative guidelines, and trust in proven practices to harness the full potential of expanded metal meshes.

Share

Next:

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025