Welcome to our websites!

1 月 . 28, 2025 02:26 Back to list

galvanized steel gabion net, galvanized gabion factory

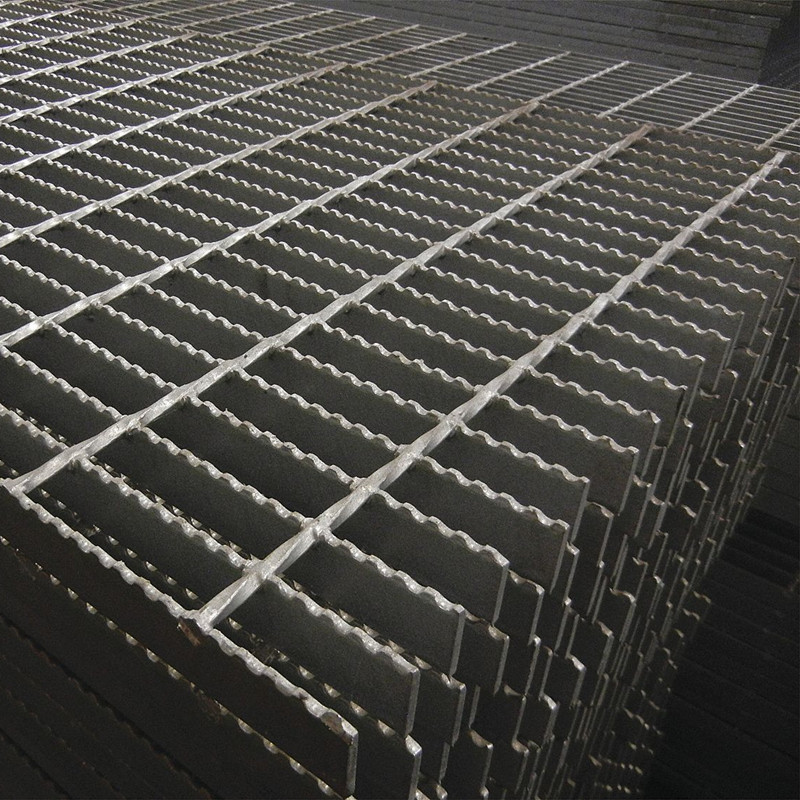

Galvanized steel gabion nets have grown in popularity due to their versatile applications in construction and landscaping. These nets, produced by specialized galvanized gabion factories, are notable for their durability, adaptability, and cost-effectiveness. Their production and application require a deep understanding of materials, engineering, and environmental considerations.

Professionals in engineering and construction choose galvanized gabions not only for their durability but also for the aesthetic flexibility they offer. Filled with natural stone, gabions can blend seamlessly with their surroundings, providing both functional and visual enhancements to urban and rural landscapes. Landscape architects appreciate how gabions integrate with nature, favoring their use in environmentally conscious designs. Gabion structures are easy to install, usually requiring minimal machinery. Their modular design allows for quick assembly and placement, saving time and resources on the project site. This ease of installation contributes to their appeal in projects that demand rapid deployment and adaptability to terrain variations. Trustworthiness in the context of procuring gabion materials comes down to certifications and client testimonials. When selecting a galvanized gabion factory, it is crucial to consider their industry certifications which verify quality standards and adherence to international guidelines. Buyers should seek out reviews or case studies from previous clients to gauge the reliability and performance of the factory’s gabions under real-world conditions. In conclusion, the strength of a galvanized gabion lies in both its material properties and the manufacturing process it undergoes. Factories specializing in these products elevate their quality through advanced technology, skilled workers, and a commitment to sustainability and customer satisfaction. Whether for infrastructure development, environmental conservation, or aesthetic landscaping, galvanized steel gabion nets stand out as a resilient and versatile solution.

Professionals in engineering and construction choose galvanized gabions not only for their durability but also for the aesthetic flexibility they offer. Filled with natural stone, gabions can blend seamlessly with their surroundings, providing both functional and visual enhancements to urban and rural landscapes. Landscape architects appreciate how gabions integrate with nature, favoring their use in environmentally conscious designs. Gabion structures are easy to install, usually requiring minimal machinery. Their modular design allows for quick assembly and placement, saving time and resources on the project site. This ease of installation contributes to their appeal in projects that demand rapid deployment and adaptability to terrain variations. Trustworthiness in the context of procuring gabion materials comes down to certifications and client testimonials. When selecting a galvanized gabion factory, it is crucial to consider their industry certifications which verify quality standards and adherence to international guidelines. Buyers should seek out reviews or case studies from previous clients to gauge the reliability and performance of the factory’s gabions under real-world conditions. In conclusion, the strength of a galvanized gabion lies in both its material properties and the manufacturing process it undergoes. Factories specializing in these products elevate their quality through advanced technology, skilled workers, and a commitment to sustainability and customer satisfaction. Whether for infrastructure development, environmental conservation, or aesthetic landscaping, galvanized steel gabion nets stand out as a resilient and versatile solution.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025