Welcome to our websites!

2 月 . 01, 2025 04:23 Back to list

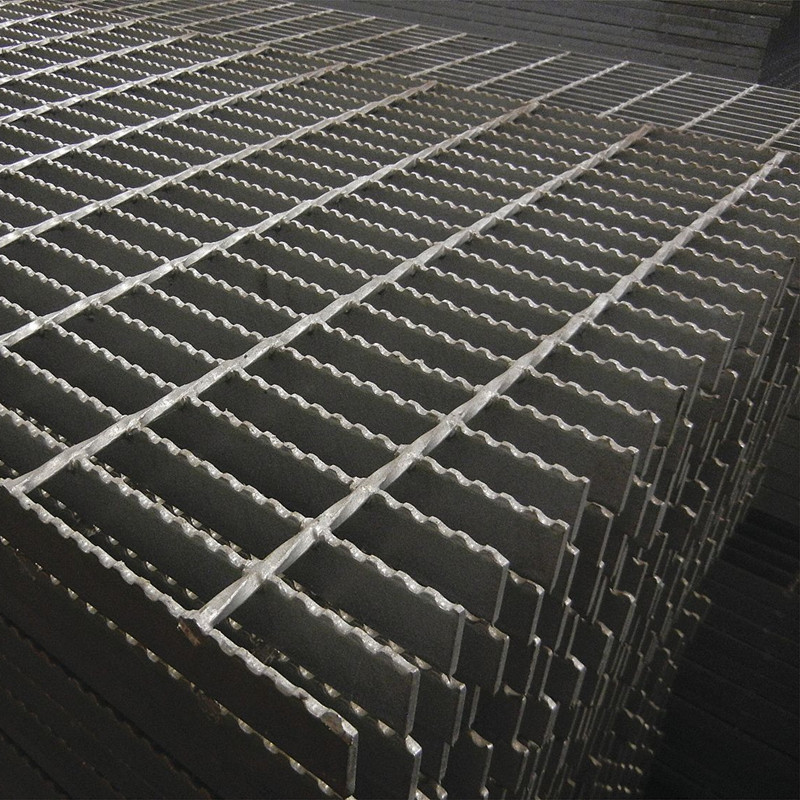

heavy duty expanded metal mesh

Heavy duty expanded metal mesh has found its place in various industries, offering a combination of strength, durability, and adaptability that makes it indispensable for numerous applications. This versatile material not only meets demanding requirements in construction and manufacturing but also enhances safety and efficiency in projects across the globe.

In terms of authoritativeness, notable organizations and safety bodies around the world have recognized heavy duty expanded metal mesh as a standard component in complex projects. For instance, it adheres to various international safety standards, ensuring that it can be deployed confidently in high-risk industrial environments. By meeting rigorous testing and certification processes, manufacturers have successfully established the mesh as a trusted solution for engineers and architects worldwide. It's also worth noting the material's exceptional longevity. Heavy duty expanded metal mesh is designed to withstand extreme environmental conditions, including exposure to harsh chemicals, high humidity, and variable temperatures. This durability reduces the need for frequent replacements and repairs, thus minimizing long-term operational costs. Industry peers often testify to its resilience, citing projects where the mesh has remained intact and functional decades after installation. Trustworthiness in heavy duty expanded metal mesh's applications is further underscored by customer testimonials and case studies demonstrating its performance. Decision-makers can learn from these real-world examples, relying on documented outcomes to guide their choice of materials. Through such evidence, the consistency and efficacy of the material in delivering high-quality results are meticulously substantiated. In conclusion, heavy duty expanded metal mesh is more than just a tool—it's a groundbreaking solution that addresses numerous challenges across various industries. Its ability to provide strength without the weight, coupled with its durability and versatility, makes it an outstanding choice for construction and industrial applications. As a professional deeply familiar with the intricacies of this material, I advocate for its continued use and innovation, confident that its benefits will only expand as industries evolve and adapt to new challenges.

In terms of authoritativeness, notable organizations and safety bodies around the world have recognized heavy duty expanded metal mesh as a standard component in complex projects. For instance, it adheres to various international safety standards, ensuring that it can be deployed confidently in high-risk industrial environments. By meeting rigorous testing and certification processes, manufacturers have successfully established the mesh as a trusted solution for engineers and architects worldwide. It's also worth noting the material's exceptional longevity. Heavy duty expanded metal mesh is designed to withstand extreme environmental conditions, including exposure to harsh chemicals, high humidity, and variable temperatures. This durability reduces the need for frequent replacements and repairs, thus minimizing long-term operational costs. Industry peers often testify to its resilience, citing projects where the mesh has remained intact and functional decades after installation. Trustworthiness in heavy duty expanded metal mesh's applications is further underscored by customer testimonials and case studies demonstrating its performance. Decision-makers can learn from these real-world examples, relying on documented outcomes to guide their choice of materials. Through such evidence, the consistency and efficacy of the material in delivering high-quality results are meticulously substantiated. In conclusion, heavy duty expanded metal mesh is more than just a tool—it's a groundbreaking solution that addresses numerous challenges across various industries. Its ability to provide strength without the weight, coupled with its durability and versatility, makes it an outstanding choice for construction and industrial applications. As a professional deeply familiar with the intricacies of this material, I advocate for its continued use and innovation, confident that its benefits will only expand as industries evolve and adapt to new challenges.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025