8 月 . 18, 2024 00:31 Back to list

Manufacturers of High-Quality PVC Coated Gabion Baskets for Versatile Landscaping Solutions

PVC Coated Gabion Baskets An Overview of Their Manufacturing Process

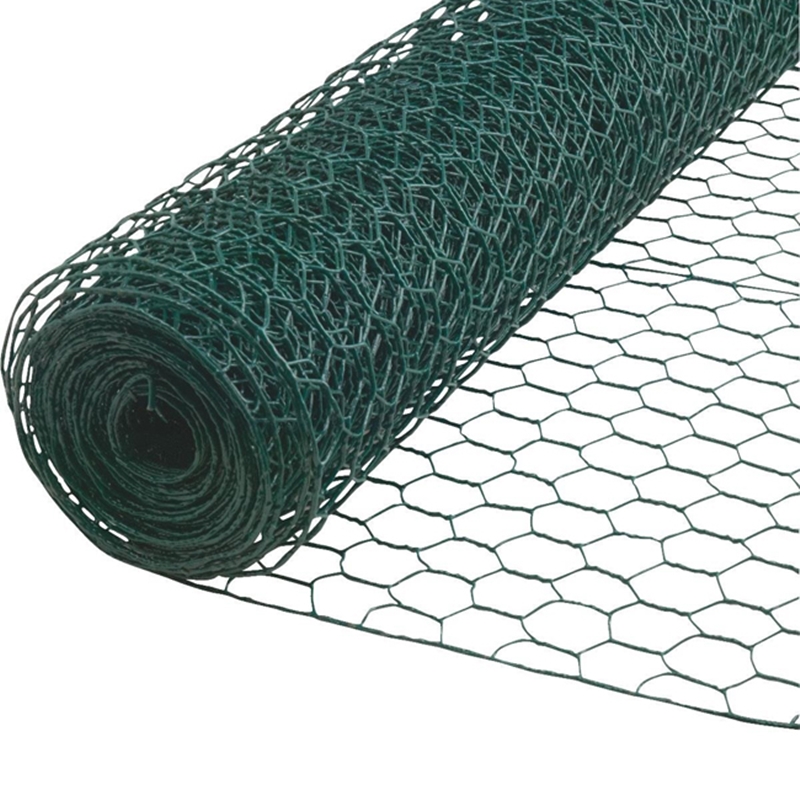

Gabion baskets have become increasingly popular in civil engineering and landscaping due to their versatility, strength, and aesthetic appeal. Among the various types of gabions available, PVC coated gabion baskets are particularly noteworthy. These baskets consist of wire mesh filled with stones or gravel, designed to provide effective solutions for erosion control, retaining walls, and decorative landscaping. Understanding the manufacturing process of these specialized gabion baskets sheds light on their effectiveness and durability.

The Materials Used

The primary component of PVC coated gabion baskets is steel wire, typically made from high-quality low-carbon steel. The wire is initially galvanized to protect it from corrosion and to ensure longevity, especially in outdoor applications. The galvanization process is crucial as it provides a protective layer against environmental factors, enhancing the basket's lifespan significantly.

After the steel wire undergoes the galvanization process, it is then coated with PVC (polyvinyl chloride). This additional layer offers a double layer of protection against corrosion, UV rays, and chemical exposure, making PVC coated gabion baskets an ideal choice for environments that are prone to harsh weather conditions. The PVC coating also adds an aesthetic touch, allowing baskets to blend in with the natural surroundings, which is a significant consideration in landscaping projects.

Manufacturing Process

The manufacturing of PVC coated gabion baskets typically involves several key steps

1. Wire Preparation The manufacturing begins with selecting high-quality steel wire. The wire is cut to specific lengths and pre-treated to prepare it for galvanization.

2. Galvanization The cut wire is then submerged in a molten bath of zinc, allowing for a thorough coating that protects against corrosion. The galvanized wire is then left to cool and solidify, forming a robust protective layer.

3. PVC Coating After galvanization, the wire undergoes a PVC coating process. The wire is extruded through a heated chamber where the PVC material is applied. The coating thickness can be adjusted based on the intended use of the gabion basket.

pvc coated gabion basket factories

4. Mesh Fabrication Once the wires are coated and cooled, they are woven into mesh panels. This weaving process can vary based on the design specifications for the gabion baskets.

5. Formation of Baskets The woven mesh is then formed into the shape of a basket. This can be done manually or with the help of automated machinery. Baskets are made to various dimensions to meet the specific needs of customers.

6. Quality Control Throughout the manufacturing process, rigorous quality control measures are implemented. This includes testing the tensile strength of the wire, ensuring proper coating thickness, and inspecting the final assembled baskets for any defects.

Applications and Advantages

PVC coated gabion baskets are used in various applications, including

- Erosion Control They are widely used to prevent soil erosion on slopes and riverbanks. - Retaining Walls The strength of galionic wire meshed with stone makes them ideal for building robust retaining walls. - Landscaping They serve decorative purposes in gardens and parks, enhancing aesthetic appeal while providing structural support.

In addition to their versatile applications, the advantages of using PVC coated gabion baskets are numerous. The dual protection against corrosion and UV degradation ensures a long lifespan, making them a cost-effective solution in the long term. Additionally, the ease of installation and the ability to source local materials for filling enhance their attractiveness as a choice for various construction and landscaping projects.

Conclusion

In conclusion, PVC coated gabion baskets represent a blend of durability, functionality, and aesthetic appeal in modern construction and landscaping. Their robust manufacturing process ensures that they meet the demands of various applications, ultimately contributing to environmental sustainability and aesthetic enhancement in our built environment. With the world increasingly focused on resilient construction practices, the use of PVC coated gabion baskets will likely continue to rise, providing effective solutions for a range of challenges in civil engineering and landscape design.

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025