Welcome to our websites!

2 月 . 13, 2025 23:03 Back to list

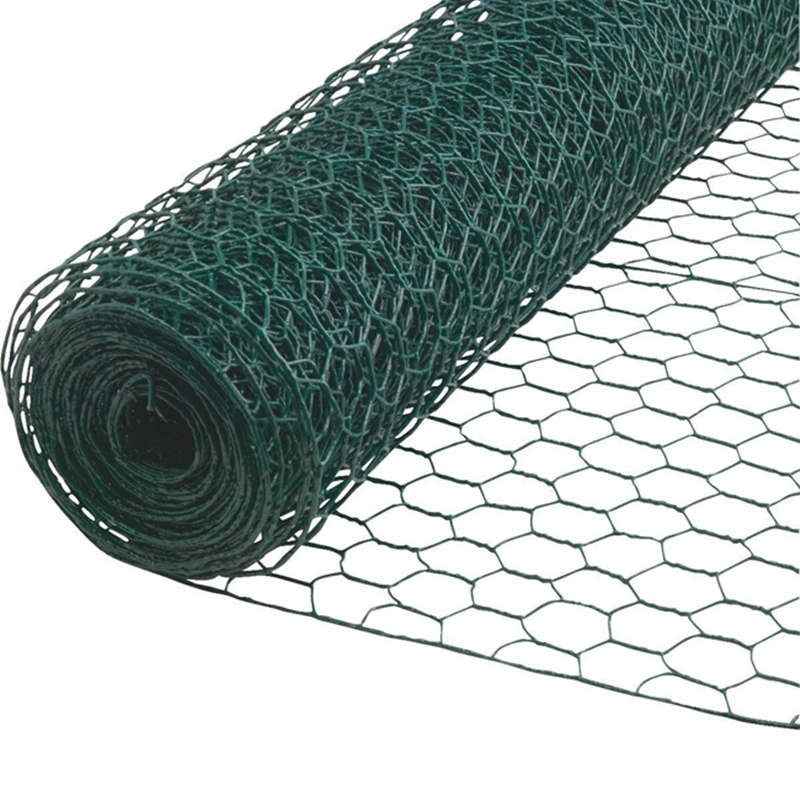

mesh for chain link fence

Chain link fences have long been a popular choice for both residential and commercial properties due to their durability and cost-effectiveness. However, a fundamental component often overlooked is the mesh used in these fences. Choosing the right mesh for a chain link fence can significantly affect its functionality, lifespan, and suitability for various applications. This article explores critical insights into selecting and utilizing the ideal mesh for chain link fences, emphasizing real-world experience, professional expertise, authoritative guidelines, and trusted practices.

Beyond the technical aspects of material, gauge, and size, installation expertise and environmental adaptations also play pivotal roles. Professional installation ensures the mesh is tensioned correctly to avoid sagging or gaps, which can compromise the fence's security. Furthermore, in regions prone to high winds or heavy snowfall, reinforcing posts and connections can prevent structural failures. It's also advisable to consider local wildlife and vegetation, which might necessitate specific mesh features, such as narrower apertures to keep out small animals. For authoritative guidance, industry standards such as those provided by the ASTM International (American Society for Testing and Materials) offer detailed specifications covering mesh materials, sizes, and testing procedures. Adhering to these standards ensures the mesh used in a chain link fence meets recognized quality and safety benchmarks, building trust with clients and stakeholders. Real-world installations provide invaluable feedback on the performance of different meshes under diverse conditions. Consulting case studies or seeking referrals from similar projects can illuminate mesh choices that have proven successful or problematic over time. Moreover, continually updating one's knowledge regarding advances in manufacturing technologies or emerging materials, such as eco-friendly options, can present opportunities to incorporate novel solutions that offer enhanced benefits. Ultimately, the suitability of a particular mesh for a chain link fence arises from a confluence of insightful evaluations regarding material, gauge, and mesh size, reinforced by professional installation and adherence to recognized standards. A nuanced approach that considers both immediate needs and long-term implications will ensure the fencing solution not only meets current requirements but also anticipates future challenges, consistently delivering reliability and peace of mind.

Beyond the technical aspects of material, gauge, and size, installation expertise and environmental adaptations also play pivotal roles. Professional installation ensures the mesh is tensioned correctly to avoid sagging or gaps, which can compromise the fence's security. Furthermore, in regions prone to high winds or heavy snowfall, reinforcing posts and connections can prevent structural failures. It's also advisable to consider local wildlife and vegetation, which might necessitate specific mesh features, such as narrower apertures to keep out small animals. For authoritative guidance, industry standards such as those provided by the ASTM International (American Society for Testing and Materials) offer detailed specifications covering mesh materials, sizes, and testing procedures. Adhering to these standards ensures the mesh used in a chain link fence meets recognized quality and safety benchmarks, building trust with clients and stakeholders. Real-world installations provide invaluable feedback on the performance of different meshes under diverse conditions. Consulting case studies or seeking referrals from similar projects can illuminate mesh choices that have proven successful or problematic over time. Moreover, continually updating one's knowledge regarding advances in manufacturing technologies or emerging materials, such as eco-friendly options, can present opportunities to incorporate novel solutions that offer enhanced benefits. Ultimately, the suitability of a particular mesh for a chain link fence arises from a confluence of insightful evaluations regarding material, gauge, and mesh size, reinforced by professional installation and adherence to recognized standards. A nuanced approach that considers both immediate needs and long-term implications will ensure the fencing solution not only meets current requirements but also anticipates future challenges, consistently delivering reliability and peace of mind.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025