Welcome to our websites!

2 月 . 14, 2025 11:33 Back to list

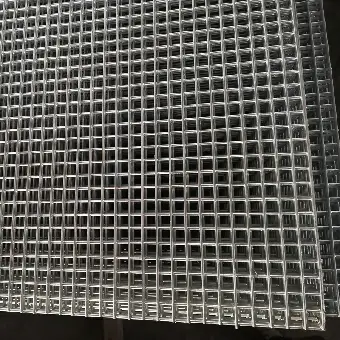

metal grating floor

Metal grating floors have become indispensable assets across various industries due to their durability, versatility, and cost-effectiveness. These flooring solutions are made by joining steal bars together, forming a sturdy grid that can support significant weight. This unique design not only makes them an ideal option for industrial applications but also provides enhanced safety through slip resistance, essential in environments exposed to moisture and other challenging conditions.

Regarding economic effectiveness, the implementation of metal grating floors is remarkably cost-efficient. Despite the initial investment, the long-term benefits realized through reduced maintenance and replacement costs are substantial. Their durability under extreme operational conditions provides a compelling economic case for industries looking to invest in sustainable and robust infrastructure solutions. Additionally, environmental concerns are increasingly dictating industrial decisions, and in this regard, metal grating floors shine as an environmentally conscious choice. Most metal used in grating is recyclable, aligning with global sustainability goals. Their long lifecycle reduces the frequency of manufacturing new grating, indirectly lessening environmental strain. This not only fulfills corporate responsibility towards greener processes but also appeals to an eco-conscious consumer base, adding an ethical dimension to their practical application. In the context of expertise and trustworthiness, the metal flooring industry is guided by rigorous standards and certifications that ensure quality and performance. Renowned manufacturers provide comprehensive testing and quality assurance, backed by expert engineering to meet specific industrial standards. This engenders confidence among buyers that they are investing in a product that meets stringent safety and quality benchmarks. In conclusion, metal grating floors exemplify a fusion of strength, versatility, and cost-efficiency that renders them indispensable in modern industry. Their numerous applications underscore a commitment to long-term durability, operational safety, and environmental stewardship. The advanced quality controls in place further establish them as a reliable choice for organizations seeking integrated flooring solutions that can withstand the demands of today's fast-paced industrial settings. From their unparalleled load-bearing capacity to their customizable nature, metal grating floors provide not only a tangible asset but also a strategic advantage in operational planning.

Regarding economic effectiveness, the implementation of metal grating floors is remarkably cost-efficient. Despite the initial investment, the long-term benefits realized through reduced maintenance and replacement costs are substantial. Their durability under extreme operational conditions provides a compelling economic case for industries looking to invest in sustainable and robust infrastructure solutions. Additionally, environmental concerns are increasingly dictating industrial decisions, and in this regard, metal grating floors shine as an environmentally conscious choice. Most metal used in grating is recyclable, aligning with global sustainability goals. Their long lifecycle reduces the frequency of manufacturing new grating, indirectly lessening environmental strain. This not only fulfills corporate responsibility towards greener processes but also appeals to an eco-conscious consumer base, adding an ethical dimension to their practical application. In the context of expertise and trustworthiness, the metal flooring industry is guided by rigorous standards and certifications that ensure quality and performance. Renowned manufacturers provide comprehensive testing and quality assurance, backed by expert engineering to meet specific industrial standards. This engenders confidence among buyers that they are investing in a product that meets stringent safety and quality benchmarks. In conclusion, metal grating floors exemplify a fusion of strength, versatility, and cost-efficiency that renders them indispensable in modern industry. Their numerous applications underscore a commitment to long-term durability, operational safety, and environmental stewardship. The advanced quality controls in place further establish them as a reliable choice for organizations seeking integrated flooring solutions that can withstand the demands of today's fast-paced industrial settings. From their unparalleled load-bearing capacity to their customizable nature, metal grating floors provide not only a tangible asset but also a strategic advantage in operational planning.

Share

Next:

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025