Welcome to our websites!

1 月 . 20, 2025 07:46 Back to list

pvc coated welded wire mesh

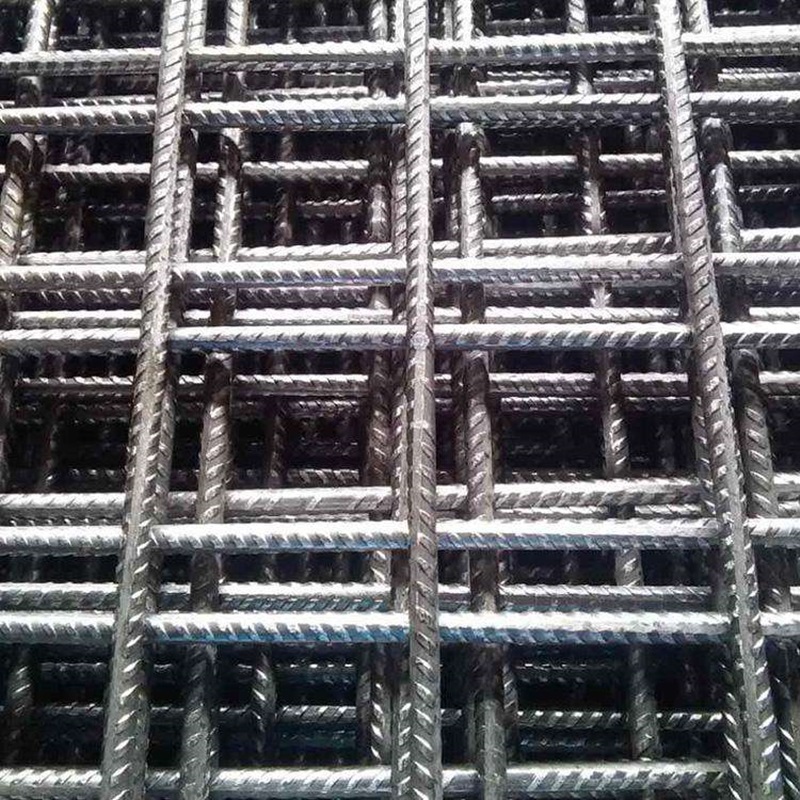

PVC coated welded wire mesh stands out as an exceptional product in both construction and agricultural sectors, owing to its durability, versatility, and corrosion resistance. Its applications are diverse, yet each utilization showcases the unique benefits of this material to industries across the globe.

Another significant advantage of the PVC coated welded wire mesh lies in its environmental adaptability. Unlike materials that suffer from temperature-induced brittleness or expansion, the PVC coating provides a buffer that accommodates temperature fluctuations. This characteristic is particularly noted by landscaping professionals and environmental engineers who utilize the mesh in projects where ground stability and structural durability are essential. When considering installation, ease of use is another factor where this mesh shines. It can be modified on-site to fit varying dimensions and land contours without loss of structural integrity. Industry leaders corroborate that the labor efficiency facilitated by the mesh leads to expedited project timelines and reduced labor costs—factors crucial in commercial and industrial applications where time equates to financial implications. In summary, the PVC coated welded wire mesh is recognized for its unparalleled performance and adaptability across multiple sectors. Its design addresses the key concerns of longevity, functionality, and return on investment, offering a reliable solution that meets the demanding standards set by professionals. With its proven track record and continuous innovation in production methods, the mesh has rightfully earned its place as a cornerstone material for modern infrastructure and agricultural methodologies. Products like these are the result of extensive research and expertise, meeting high standards of quality and authority, and are trusted by numerous industries for their varied applications.

Another significant advantage of the PVC coated welded wire mesh lies in its environmental adaptability. Unlike materials that suffer from temperature-induced brittleness or expansion, the PVC coating provides a buffer that accommodates temperature fluctuations. This characteristic is particularly noted by landscaping professionals and environmental engineers who utilize the mesh in projects where ground stability and structural durability are essential. When considering installation, ease of use is another factor where this mesh shines. It can be modified on-site to fit varying dimensions and land contours without loss of structural integrity. Industry leaders corroborate that the labor efficiency facilitated by the mesh leads to expedited project timelines and reduced labor costs—factors crucial in commercial and industrial applications where time equates to financial implications. In summary, the PVC coated welded wire mesh is recognized for its unparalleled performance and adaptability across multiple sectors. Its design addresses the key concerns of longevity, functionality, and return on investment, offering a reliable solution that meets the demanding standards set by professionals. With its proven track record and continuous innovation in production methods, the mesh has rightfully earned its place as a cornerstone material for modern infrastructure and agricultural methodologies. Products like these are the result of extensive research and expertise, meeting high standards of quality and authority, and are trusted by numerous industries for their varied applications.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025