Welcome to our websites!

2 月 . 01, 2025 06:01 Back to list

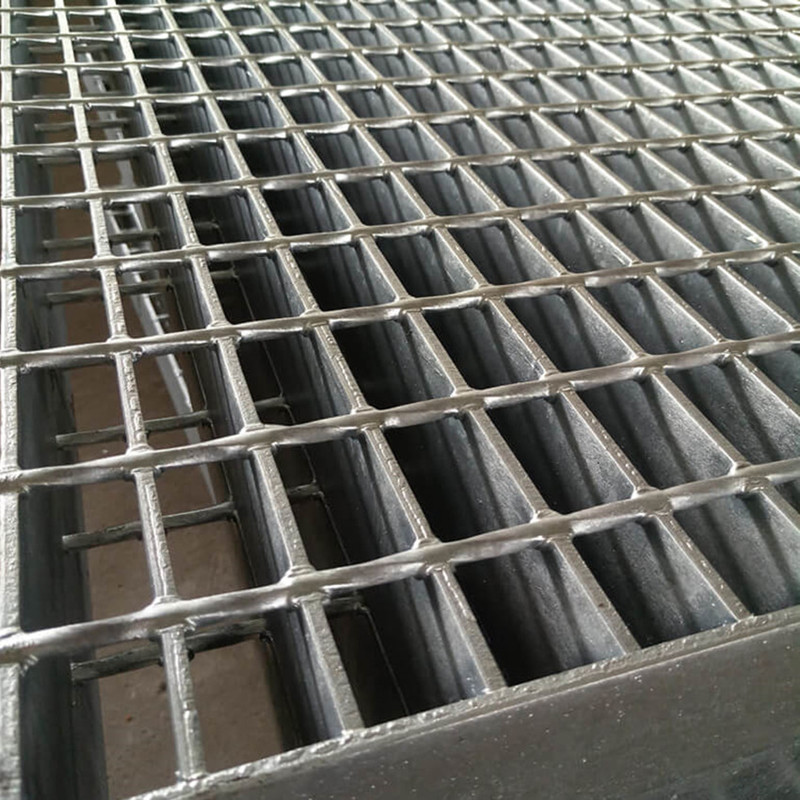

Steel Expanded Metal Mesh Fence

Raised expanded metal mesh stands as a versatile and essential component used in various industrial and architectural applications. Its structure, design, and inherent properties make it a standout choice for those seeking durability, flexibility, and aesthetic appeal. With decades of successful implementation across multiple sectors, this material commands attention and respect for its unmatched functionality.

Authoritativeness in the raised expanded metal mesh domain extends from manufacturers to engineers who champion its use. Manufacturers often provide comprehensive guidelines and specifications, ensuring precise application and installation practices. These standards guarantee optimized performance and safety, reinforcing the mesh’s reputation as a dependable choice. Similarly, engineering experts frequently endorse its incorporation into designs requiring load-bearing capability and resilience, further cementing its standing as a foundational component in critical projects worldwide. The credibility or trustworthiness of raised expanded metal mesh products is largely built on documented success stories and proven applications. Case studies featuring its deployment in demanding scenarios bolster confidence among potential users. Whether it's the robust performance in petrochemical industry terrains or its incorporation into secure facilities requiring high-level protection, the material’s reliability is well-documented and supported by empirical evidence. Moreover, certifications from established standard organizations verify its quality and compliance, providing assurance to users invested in both performance and safety. In conclusion, raised expanded metal mesh encapsulates a blend of experience, expertise, authoritativeness, and trustworthiness that few materials can rival. Its unparalleled strength-to-weight ratio, coupled with its inherent resilience and flexibility, make it an indispensable material in numerous applications. From industrial flooring to architectural aesthetics, its diverse uses reflect a product built on enduring quality and exceptional performance. Those selecting this superior material can be assured of its capability to meet demanding requirements while enhancing the visual and functional aspects of their projects.

Authoritativeness in the raised expanded metal mesh domain extends from manufacturers to engineers who champion its use. Manufacturers often provide comprehensive guidelines and specifications, ensuring precise application and installation practices. These standards guarantee optimized performance and safety, reinforcing the mesh’s reputation as a dependable choice. Similarly, engineering experts frequently endorse its incorporation into designs requiring load-bearing capability and resilience, further cementing its standing as a foundational component in critical projects worldwide. The credibility or trustworthiness of raised expanded metal mesh products is largely built on documented success stories and proven applications. Case studies featuring its deployment in demanding scenarios bolster confidence among potential users. Whether it's the robust performance in petrochemical industry terrains or its incorporation into secure facilities requiring high-level protection, the material’s reliability is well-documented and supported by empirical evidence. Moreover, certifications from established standard organizations verify its quality and compliance, providing assurance to users invested in both performance and safety. In conclusion, raised expanded metal mesh encapsulates a blend of experience, expertise, authoritativeness, and trustworthiness that few materials can rival. Its unparalleled strength-to-weight ratio, coupled with its inherent resilience and flexibility, make it an indispensable material in numerous applications. From industrial flooring to architectural aesthetics, its diverse uses reflect a product built on enduring quality and exceptional performance. Those selecting this superior material can be assured of its capability to meet demanding requirements while enhancing the visual and functional aspects of their projects.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025