8 月 . 21, 2024 21:16 Back to list

Top Manufacturers of Premium Flat Steel Bar Grating for Industrial Applications

High-Quality Flat Steel Bar Grating Manufacturers A Detailed Insight

In the construction and manufacturing industries, flat steel bar grating serves as a critical component for various applications. From flooring systems to drainage covers, these gratings are known for their strength, durability, and versatility. As the demand for such products rises, several manufacturers have emerged in the market, focusing on high-quality production standards. This article delves into the key aspects of high-quality flat steel bar grating manufacturers and what sets them apart.

Understanding Flat Steel Bar Grating

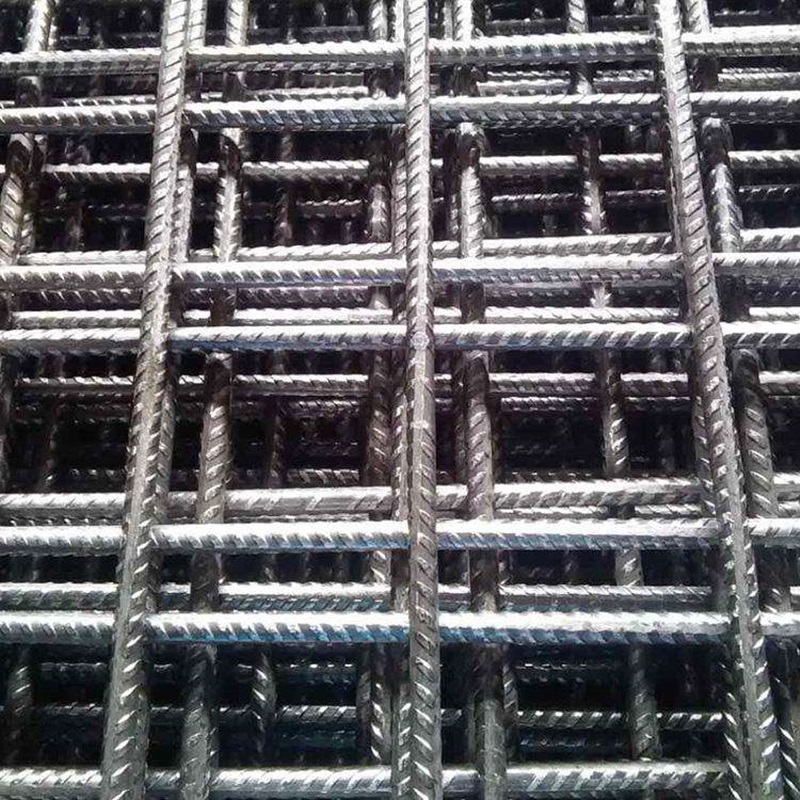

Flat steel bar grating is fabricated from flat bars, which are typically made of carbon steel or stainless steel. These bars are arranged in a parallel fashion and are welded or mechanically fastened to create a strong, durable grid. The spacing between the bars can vary depending on the load requirements and specific applications. This form of grating is widely used in industrial settings such as factories, warehouses, and outdoor environments due to its excellent load-bearing capacity and resistance to heavy impacts.

What to Look for in High-Quality Manufacturers

1. Material Quality The primary factor that distinguishes high-quality flat steel bar grating is the material used. Top manufacturers source premium-grade steel that meets international standards. This ensures that the resulting product can withstand harsh environments, resist corrosion, and endure high traffic loads.

2. Manufacturing Process Advanced manufacturing processes are crucial for producing flat steel gratings that exhibit structural integrity and longevity. Reputable manufacturers employ cutting-edge technology such as CNC machining, laser cutting, and automated welding techniques to ensure precision in their products. Rigorous quality control measures are often implemented throughout the production process to maintain consistency and reliability.

high quality flat steel bar grating manufacturers

3. Customization Options High-quality manufacturers understand that each project has unique requirements. Therefore, they offer customization options for their flat steel bar gratings, including different sizes, spacing configurations, and finishes. Clients can specify dimensions and load ratings to ensure the product fits their specific application, whether for architectural projects, walkways, or mezzanines.

4. Certifications and Compliance The best manufacturers are compliant with industry standards and hold relevant certifications. These certifications demonstrate their commitment to quality and safety. ISO 9001 and ASTM standards are common benchmarks in the industry, ensuring that the products meet or exceed market expectations.

5. Customer Support and Service Engaging with a manufacturer that provides excellent customer support is essential. High-quality manufacturers often have knowledgeable staff who can assist clients in selecting the right product for their needs. After-sales support, including installation guidance and product warranties, further enhances the customer's experience.

6. Reputation and Experience Established manufacturers with a strong track record are often more reliable than newer or lesser-known companies. Their experience in the industry usually translates to superior production techniques, better customer service, and increased innovation. Researching customer reviews and case studies can provide insights into a manufacturer’s reliability and product performance.

Conclusion

In conclusion, high-quality flat steel bar grating manufacturers play a pivotal role in delivering robust and reliable solutions for various industrial applications. Their commitment to using premium materials, advanced manufacturing processes, customization options, and adherence to industry standards sets them apart in a competitive market. By choosing the right manufacturer, companies can ensure that they receive products that not only meet their specifications but also stand the test of time in demanding environments. Through continuous innovation and a focus on quality, these manufacturers contribute significantly to the efficiency and safety of construction projects worldwide.

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025