Welcome to our websites!

6 月 . 15, 2024 18:28 Back to list

We specialize in welded wire mesh manufacturing.

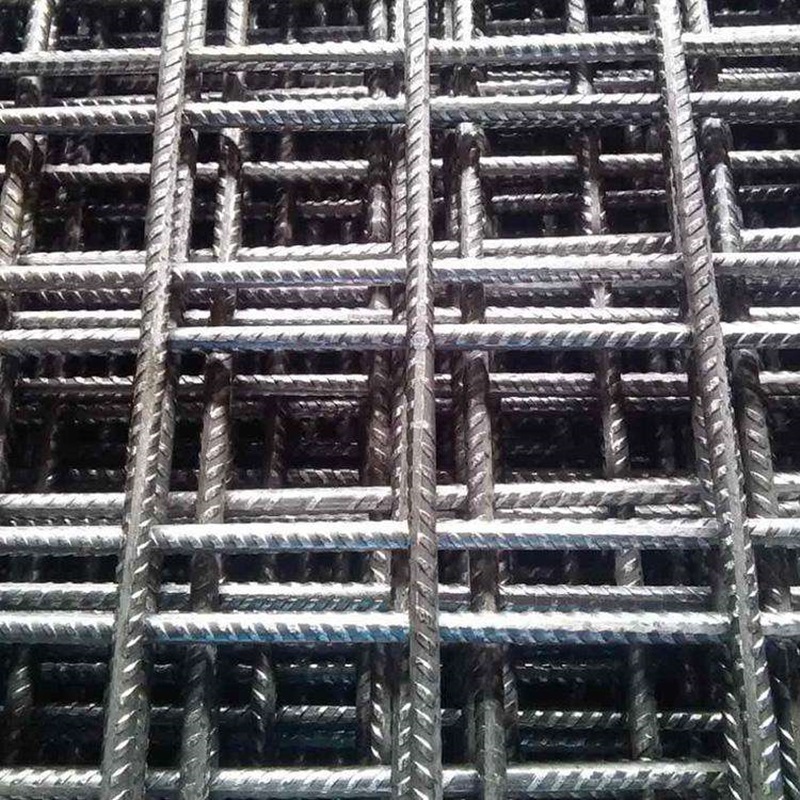

The Craft and Commitment of a Welded Wire Mesh Factory

In the realm of industrial manufacturing, the welded wire mesh factory stands as a testament to precision, innovation, and reliability. These specialized facilities are dedicated to the production of high-quality wire mesh products that cater to a myriad of applications across various sectors.

The process begins with selecting the appropriate raw materials. Quality stainless steel, galvanized iron, or aluminum wires are meticulously chosen based on the end-use requirements—be it for architectural decor, industrial filtration, or agricultural enclosures. The wires are then fed into automated machines where they undergo a process of welding. This step is crucial as it ensures the structural integrity of the mesh by creating strong weld points at each intersection of wires.

Technological advancements have played a significant role in enhancing the efficiency and consistency of welded wire mesh production. Computer-controlled machinery precisely cuts, welds, and forms the mesh to exact specifications, thereby minimizing waste and maximizing output. The mesh is then straightened and surface treated—a process that could involve hot-dip galvanizing, PVC coating, or electropolishing to ensure durability and resistance to environmental factors.

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices welded wire mesh factory. Rigorous quality control measures are implemented at every stage of production to guarantee that the final product meets international standards. Meanwhile, efforts to minimize the environmental footprint are evident in recycling programs and the use of eco-friendly materials and processes.

The versatility of welded wire mesh products is another point of pride for these factories. From robust animal enclosures and fruit harvesting supports to elegant architectural facades and custom interior designs, the adaptability of wire mesh knows few bounds. It is this very adaptability that keeps the industry dynamic and continuously seeking new avenues for innovation.

In conclusion, the operations of a welded wire mesh factory are a blend of technological prowess, dedication to quality, and an ongoing commitment to sustainability. These facilities are not just manufacturers but craftsmen of versatile solutions that permeate various aspects of modern life. As they continue to evolve with emerging technologies and market demands, their impact on industry and society is set to expand, solidifying their role as key players in the industrial fabric.

welded wire mesh factory. Rigorous quality control measures are implemented at every stage of production to guarantee that the final product meets international standards. Meanwhile, efforts to minimize the environmental footprint are evident in recycling programs and the use of eco-friendly materials and processes.

The versatility of welded wire mesh products is another point of pride for these factories. From robust animal enclosures and fruit harvesting supports to elegant architectural facades and custom interior designs, the adaptability of wire mesh knows few bounds. It is this very adaptability that keeps the industry dynamic and continuously seeking new avenues for innovation.

In conclusion, the operations of a welded wire mesh factory are a blend of technological prowess, dedication to quality, and an ongoing commitment to sustainability. These facilities are not just manufacturers but craftsmen of versatile solutions that permeate various aspects of modern life. As they continue to evolve with emerging technologies and market demands, their impact on industry and society is set to expand, solidifying their role as key players in the industrial fabric.

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices

One of the hallmark commitments of a welded wire mesh factory is its adherence to quality standards and sustainability practices welded wire mesh factory. Rigorous quality control measures are implemented at every stage of production to guarantee that the final product meets international standards. Meanwhile, efforts to minimize the environmental footprint are evident in recycling programs and the use of eco-friendly materials and processes.

The versatility of welded wire mesh products is another point of pride for these factories. From robust animal enclosures and fruit harvesting supports to elegant architectural facades and custom interior designs, the adaptability of wire mesh knows few bounds. It is this very adaptability that keeps the industry dynamic and continuously seeking new avenues for innovation.

In conclusion, the operations of a welded wire mesh factory are a blend of technological prowess, dedication to quality, and an ongoing commitment to sustainability. These facilities are not just manufacturers but craftsmen of versatile solutions that permeate various aspects of modern life. As they continue to evolve with emerging technologies and market demands, their impact on industry and society is set to expand, solidifying their role as key players in the industrial fabric.

welded wire mesh factory. Rigorous quality control measures are implemented at every stage of production to guarantee that the final product meets international standards. Meanwhile, efforts to minimize the environmental footprint are evident in recycling programs and the use of eco-friendly materials and processes.

The versatility of welded wire mesh products is another point of pride for these factories. From robust animal enclosures and fruit harvesting supports to elegant architectural facades and custom interior designs, the adaptability of wire mesh knows few bounds. It is this very adaptability that keeps the industry dynamic and continuously seeking new avenues for innovation.

In conclusion, the operations of a welded wire mesh factory are a blend of technological prowess, dedication to quality, and an ongoing commitment to sustainability. These facilities are not just manufacturers but craftsmen of versatile solutions that permeate various aspects of modern life. As they continue to evolve with emerging technologies and market demands, their impact on industry and society is set to expand, solidifying their role as key players in the industrial fabric. Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025