Welcome to our websites!

2 月 . 14, 2025 09:42 Back to list

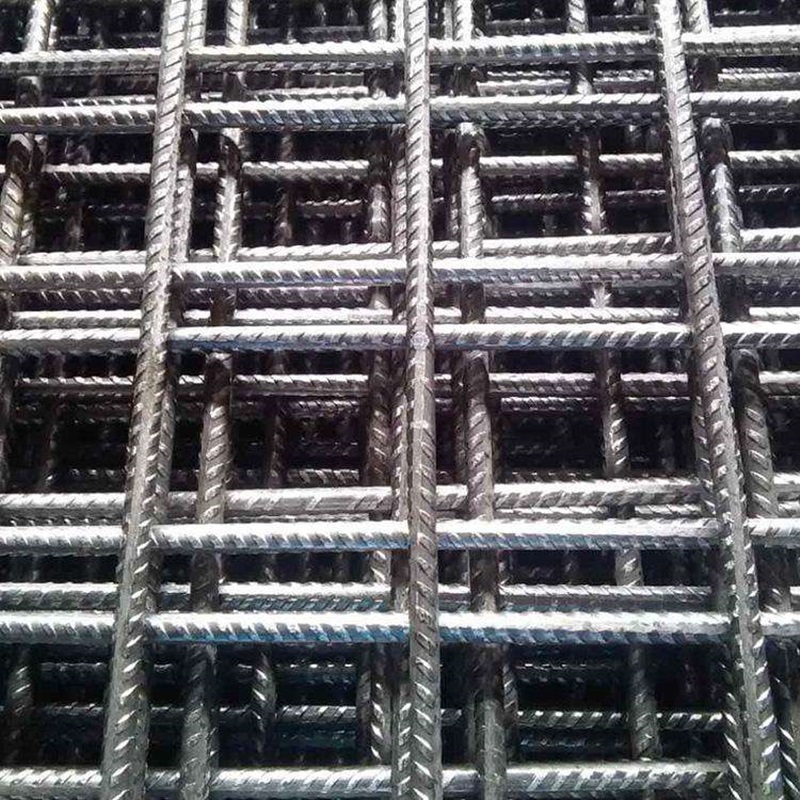

welded steel grating

Welded steel grating is a potent solution for industrial flooring, platforms, stair treads, and walkways. Expertly crafted through a process of electrical resistance welding, this product offers robust strength and flexibility, essential for environments where safety and durability are paramount.

The trustworthiness of welded steel grating as a material of choice is evidenced by its widespread use in critical infrastructure worldwide. From oil refineries to wastewater treatment facilities, its adaptability is unrivaled. Engineers and architects vouch for its longevity and minimal maintenance requirement qualities that make it economically advantageous in the long term. Unlike wood or plastic alternatives, welded steel grating stands resilient against harsh chemicals and extreme weather, ensuring prolonged service life and consistent performance. It's worth noting the environmental benefits of producing and utilizing welded steel grating. Steel is a recyclable material, and the production of grating from recycled steel significantly lowers its carbon footprint. This aspect aligns with global sustainability goals and appeals to environmentally conscious organizations looking to reduce their ecological impact. In essence, choosing welded steel grating is more than a practical decision—it's a strategic investment. As industries evolve and infrastructure becomes more complex, the demand for materials that can withstand rigorous use while providing safety and cost-effectiveness will only grow. It's a vital part of modern construction and engineering, one that promises reliability and excellence. Engage with suppliers and manufacturers renowned for their quality and expertise to explore the myriad of options welded steel grating has to offer. With the right partner, project-specific requirements can be customized, ensuring the highest standards of safety and functional integrity are met, thereby propelling your project towards success.

The trustworthiness of welded steel grating as a material of choice is evidenced by its widespread use in critical infrastructure worldwide. From oil refineries to wastewater treatment facilities, its adaptability is unrivaled. Engineers and architects vouch for its longevity and minimal maintenance requirement qualities that make it economically advantageous in the long term. Unlike wood or plastic alternatives, welded steel grating stands resilient against harsh chemicals and extreme weather, ensuring prolonged service life and consistent performance. It's worth noting the environmental benefits of producing and utilizing welded steel grating. Steel is a recyclable material, and the production of grating from recycled steel significantly lowers its carbon footprint. This aspect aligns with global sustainability goals and appeals to environmentally conscious organizations looking to reduce their ecological impact. In essence, choosing welded steel grating is more than a practical decision—it's a strategic investment. As industries evolve and infrastructure becomes more complex, the demand for materials that can withstand rigorous use while providing safety and cost-effectiveness will only grow. It's a vital part of modern construction and engineering, one that promises reliability and excellence. Engage with suppliers and manufacturers renowned for their quality and expertise to explore the myriad of options welded steel grating has to offer. With the right partner, project-specific requirements can be customized, ensuring the highest standards of safety and functional integrity are met, thereby propelling your project towards success.

Share

Next:

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025