Welcome to our websites!

3 月 . 04, 2025 12:25 Back to list

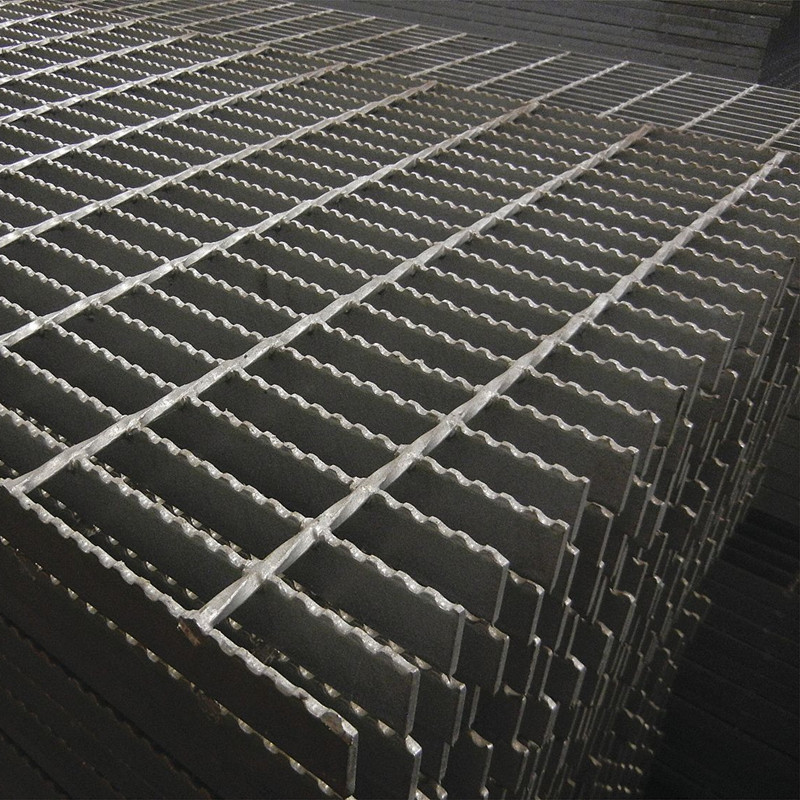

Steel Expanded Metal Mesh Fence

Selecting the right wholesale scaffold plank is a crucial decision for construction companies, safety managers, and procurement specialists who prioritize reliable, long-lasting materials for their projects. The world of scaffold planks might seem straightforward, but there are key factors that influence safety, efficiency, and overall project outcome that one must consider.

Authoritativeness in scaffold plank selection comes from understanding the global standards and regulations that define scaffold safety and usage. Ensuring that scaffold planks comply with recognized safety standards is non-negotiable for any construction entity that prioritizes worker safety. Certifications and compliance information should be readily available from reputable wholesale suppliers. Collaborating with companies that have a track record of adherence to such standards ensures that the planks will meet safety expectations and legal requirements. The trustworthiness of a wholesale scaffold plank supplier hinges on their transparency and reliability. Suppliers that offer detailed product information, including material specifications, load ratings, warranty details, and performance data, demonstrate a commitment to quality and safety. Engaging with suppliers who have a well-documented process of quality control and who provide customer testimonials or case studies can further affirm the credibility of their products. Additionally, sourcing scaffold planks from suppliers who prioritize sustainability in their manufacturing processes can enhance a company's ethical standing and commitment to environmentally friendly practices. Many forward-thinking suppliers are moving towards more sustainable materials and processes, aligning with global environmental goals and reducing overall carbon footprints. Ultimately, the decision to purchase wholesale scaffold planks should not be based solely on cost. While economic considerations are important, they should not overshadow the aspects of safety, compliance, reliability, and environmental impact. Building a relationship with reputable suppliers known for their quality and service can greatly influence the success and safety of a construction project. In conclusion, the sourcing of wholesale scaffold planks requires careful consideration of material type, compliance with safety standards, supplier reliability, and potential environmental impacts. By making informed choices grounded in experience, expertise, authoritativeness, and trustworthiness, construction companies can ensure the safety and efficiency of their scaffolding systems while upholding high standards of quality and ethical responsibility.

Authoritativeness in scaffold plank selection comes from understanding the global standards and regulations that define scaffold safety and usage. Ensuring that scaffold planks comply with recognized safety standards is non-negotiable for any construction entity that prioritizes worker safety. Certifications and compliance information should be readily available from reputable wholesale suppliers. Collaborating with companies that have a track record of adherence to such standards ensures that the planks will meet safety expectations and legal requirements. The trustworthiness of a wholesale scaffold plank supplier hinges on their transparency and reliability. Suppliers that offer detailed product information, including material specifications, load ratings, warranty details, and performance data, demonstrate a commitment to quality and safety. Engaging with suppliers who have a well-documented process of quality control and who provide customer testimonials or case studies can further affirm the credibility of their products. Additionally, sourcing scaffold planks from suppliers who prioritize sustainability in their manufacturing processes can enhance a company's ethical standing and commitment to environmentally friendly practices. Many forward-thinking suppliers are moving towards more sustainable materials and processes, aligning with global environmental goals and reducing overall carbon footprints. Ultimately, the decision to purchase wholesale scaffold planks should not be based solely on cost. While economic considerations are important, they should not overshadow the aspects of safety, compliance, reliability, and environmental impact. Building a relationship with reputable suppliers known for their quality and service can greatly influence the success and safety of a construction project. In conclusion, the sourcing of wholesale scaffold planks requires careful consideration of material type, compliance with safety standards, supplier reliability, and potential environmental impacts. By making informed choices grounded in experience, expertise, authoritativeness, and trustworthiness, construction companies can ensure the safety and efficiency of their scaffolding systems while upholding high standards of quality and ethical responsibility.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025