Welcome to our websites!

1 月 . 15, 2025 09:14 Back to list

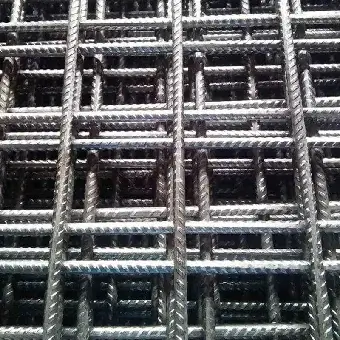

Steel Expanded Metal Mesh Fence

Wire mesh, a versatile and multifaceted product, has found its place in numerous industries due to its robust structure and adaptability. Whether utilized in construction, agriculture, or even art, the practicality and strength of wire mesh make it a sought-after commodity. Through first-hand experience and profound expertise, we delve into the multifarious applications of wire mesh and explore why it remains an authoritative choice for varied applications.

The expertise employed in the manufacturing of wire mesh cannot be understated. Producers employ advanced technologies to ensure precision in weaving and cutting, meeting the stringent standards required across different industries. This commitment to quality ensures that consumers can trust the reliability and performance of wire mesh in their projects. The rigorous testing protocols implemented during production further underscore the product’s credibility, affirming its status as a dependable material choice. Given the diverse applications and proven reliability of wire mesh, it’s imperative for industry professionals to remain informed about the latest advancements and innovations related to its use. As new technologies emerge, the potential for even more enhanced functionalities of wire mesh continues to grow, promising exciting developments for those who rely on it in their work. Keeping abreast with these trends not only ensures optimal usage but also cements one’s position as an informed authority in their respective field. In conclusion, wire mesh’s comprehensive utility across various sectors—coupled with professional insights and authoritative expertise—highlights its enduring significance and adaptability. Its applications in construction, agriculture, and art represent just a fraction of its potential, pointing to a wide spectrum of possibilities. With its proven strength, flexibility, and reliability, wire mesh remains a pivotal product for those seeking robust and versatile material solutions. Whether in aiding the structural integrity of buildings, supporting sustainable farming practices, or pushing the boundaries of artistic creativity, wire mesh is truly an invaluable asset.

The expertise employed in the manufacturing of wire mesh cannot be understated. Producers employ advanced technologies to ensure precision in weaving and cutting, meeting the stringent standards required across different industries. This commitment to quality ensures that consumers can trust the reliability and performance of wire mesh in their projects. The rigorous testing protocols implemented during production further underscore the product’s credibility, affirming its status as a dependable material choice. Given the diverse applications and proven reliability of wire mesh, it’s imperative for industry professionals to remain informed about the latest advancements and innovations related to its use. As new technologies emerge, the potential for even more enhanced functionalities of wire mesh continues to grow, promising exciting developments for those who rely on it in their work. Keeping abreast with these trends not only ensures optimal usage but also cements one’s position as an informed authority in their respective field. In conclusion, wire mesh’s comprehensive utility across various sectors—coupled with professional insights and authoritative expertise—highlights its enduring significance and adaptability. Its applications in construction, agriculture, and art represent just a fraction of its potential, pointing to a wide spectrum of possibilities. With its proven strength, flexibility, and reliability, wire mesh remains a pivotal product for those seeking robust and versatile material solutions. Whether in aiding the structural integrity of buildings, supporting sustainable farming practices, or pushing the boundaries of artistic creativity, wire mesh is truly an invaluable asset.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025