Welcome to our websites!

2 月 . 01, 2025 03:59 Back to list

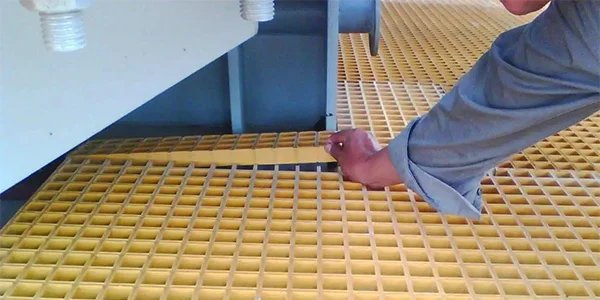

flattened expanded metal mesh

Flattened expanded metal mesh stands out as a remarkable material used across various industries, recognized for its durability, flexibility, and high strength-to-weight ratio. This material combines traditional crafting techniques with modern engineering, offering a range of benefits that stem from its unique manufacturing process. Understanding the intricacies of flattened expanded metal mesh can ensure it meets the demands of different projects, from construction to artistic applications.

The sustainability of flattened expanded metal mesh adds another layer of appeal. Manufacturing processes optimize material use, producing minimal waste compared to traditional metal cutting, and the resulting product is fully recyclable. This not only reduces the environmental impact but also lowers costs for projects focused on sustainable construction practices. In terms of expertise, leading manufacturers employ precise control over the expansion and flattening processes to produce mesh that meets rigorous industry standards. They utilize state-of-the-art technology to dictate parameters like mesh thickness, strand width, and size of the openings, ensuring that the final product aligns with specific project requirements. The authority of flattened expanded metal mesh as a product comes from its extensive track record across various sectors. Historical data and countless successful installations serve as testimonies to its reliability and versatility. Expert endorsements and case studies further cement the material's standing, providing potential users with confidence in their choice. When it comes to trustworthiness, the long lifespan and low maintenance of flattened expanded metal mesh reflect its inherent reliability. It withstands harsh weather conditions and resists corrosion, particularly in stainless steel and aluminum variants, making it suitable for outdoor use. Users can trust in the low lifecycle costs and minimal repairs needed, providing peace of mind in their investment. In conclusion, flattened expanded metal mesh is a multifaceted material that epitomizes ingenuity in metalwork. Its application is as broad as it is deep, accommodating projects that demand a balance of form and function. Its endurance and adaptability make it an invaluable resource for industries that value longevity and design flexibility. When leveraging such a product, professionals can reap the benefits of modern metalworking innovation—sustainably, safely, and stylishly.

The sustainability of flattened expanded metal mesh adds another layer of appeal. Manufacturing processes optimize material use, producing minimal waste compared to traditional metal cutting, and the resulting product is fully recyclable. This not only reduces the environmental impact but also lowers costs for projects focused on sustainable construction practices. In terms of expertise, leading manufacturers employ precise control over the expansion and flattening processes to produce mesh that meets rigorous industry standards. They utilize state-of-the-art technology to dictate parameters like mesh thickness, strand width, and size of the openings, ensuring that the final product aligns with specific project requirements. The authority of flattened expanded metal mesh as a product comes from its extensive track record across various sectors. Historical data and countless successful installations serve as testimonies to its reliability and versatility. Expert endorsements and case studies further cement the material's standing, providing potential users with confidence in their choice. When it comes to trustworthiness, the long lifespan and low maintenance of flattened expanded metal mesh reflect its inherent reliability. It withstands harsh weather conditions and resists corrosion, particularly in stainless steel and aluminum variants, making it suitable for outdoor use. Users can trust in the low lifecycle costs and minimal repairs needed, providing peace of mind in their investment. In conclusion, flattened expanded metal mesh is a multifaceted material that epitomizes ingenuity in metalwork. Its application is as broad as it is deep, accommodating projects that demand a balance of form and function. Its endurance and adaptability make it an invaluable resource for industries that value longevity and design flexibility. When leveraging such a product, professionals can reap the benefits of modern metalworking innovation—sustainably, safely, and stylishly.

Share

Latest news

-

Temporary Fence Base Products Durable & Reliable Manufacturer Solutions

NewsMay.30,2025

-

Best Africa Chicken Netting Hexagonal Wire Mesh Durable & Weatherproof

NewsMay.30,2025

-

Australian Temporary Fence Solutions Durable & Reliable Products

NewsMay.30,2025

-

Galvanized Steel Gabion Net & Trusted Gabion Factory Solutions High Durability

NewsMay.29,2025

-

Top-Rated Removable Fences Durable & Easy-Install Solutions

NewsMay.29,2025

-

Steel Expanded Metal Mesh Fence

NewsMar.07,2025